The first thing that lingers when referring to temperature monitoring is a thermocouple. For any process, if accurate temperature sensing is a paramount, there comes the usage of thermocouples. The article covers the detail about what are thermocouple protection tubes. Also, how they are significant in smooth operation of thermocouples.

Table of Contents

A Glance on Thermocouple Basics

What Are Thermocouple Protection Tubes?

Types Of Thermocouple Protection Tubes

Ceramic Thermocouple protection tube

Metal Thermocouple protection tube

Key Benefits of Thermocouple Protections Tubes

A Glance on Thermocouple Basics

In simple terms thermocouple are temperature sensors measuring temperature at a specific point. Now what guides this measurement? . It has two dissimilar metal wires that are connected. Thermocouple has a PMMC instrument that measures the EMF generated and convert it as temperature values.

Speaking about the quantity or nature of the EMF generated. These are generally very minute so as in the form of millivolts or even lesser. Normally devices such as potentiometer or galvanometer are utilized to measure the quantity of EMF generated.

Uses Of a Thermocouple

Thermocouples are often prioritized in many applications due to their ruggedness and simple – reliable operation. The usage ranges from domestic type to industrial. Coming to applications requiring quick response, high temperature and light weightiness, often thermocouple is preferred. Some major usages of thermocouples are listed below

- Thermocouples are popular in food and beverage industry. They are used as sensors for monitoring oven temperature. These are also clean in place sensors and ensure accurate food chain temperature monitoring.

- Thermocouples also are integral component of extruders. Extruders require positioning of sensor tip at molten plastic that operates at high pressures. Thermocouples easy and efficiently caters to this requirement.

- Both low temperature and high temperature applications employs thermocouple. On simple terms, high temperature applications refer to furnace operations. Often type such as S, R and B thermocouples are used for such application.

- Type E, K, T and N are used in low temperature applications even at – 200 degC.

What Are Thermocouple Protection Tubes?

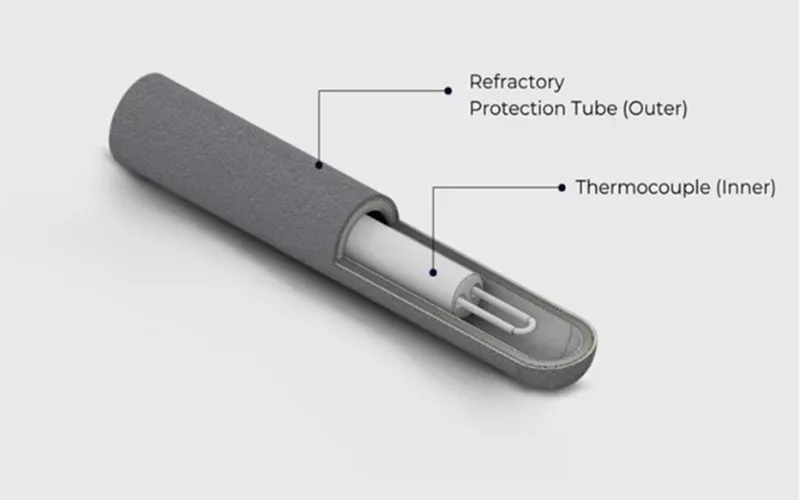

Thermocouple protection tube is one such essential component that safeguards accuracy and reliability of an operating thermocouple. It protects the thermocouple from direct heat effect and environmental concerns. Here we explore in detail on thermocouple protection tube, what are they and their key benefits if used.

Thermocouple protection tube in simple terms is something that guards the tip of a thermocouple. This is often a heat-resistant type metal that surrounds the measuring tip. It also provides insulation that results in accurate and exact temperature readings.

In the context of high temperature kiln, the protection tube guards the thermocouple from oxide dusts. The protection tube also shields the thermocouple from the negative effects of radiation. It makes sure that the instrument doesn’t generate any false readings.

Types Of Thermocouple Protection Tubes

Thermocouple protection tubes are generally made up of materials such as Silicon Carbide, Stainless steel and Alumina. They are categorized as either ceramic or metallic protection tubes. Some key properties of each type of protection tube are written for understanding.

Ceramic Thermocouple protection tube

セラミック thermocouple protection tubes are used in high temperature and corrosive applications. Ceramic by its nature can resist erosion, impact and degradation. They are resistant to heat shocks where temperature fluctuations damage the material. Since they are insulators, electrical wires can be easily transferred through the tube.

Silicon Nitride Thermocouple Protection Tube:

Silicon Nitride tubes are a type of ceramic protection tube known for its high strength. It has density of 3.2 g/cm3. They are mechanically strong and has breaking and compressive strength of 950 and 3000 MPa respectively. The fracture toughness of Silicon Nitride tube is around 5 -8.

窒化シリコン tubes are generally resistant to high thermal shocks and operates at 2000 degC. It is suitable for applications that involves random rapid temperature fluctuations. Silicon Nitride based ceramic protection tube also offers non-wettability in ferrous medium.

Alumina Protection Tube:

アルミナ thermocouple protection tube offers higher chemical resistance. They are often the type of ceramic protection tubes used in corrosive environments. The extreme purity of Alumina, let the thermocouple operate under difficult situations. The property of electrical insulation and heat conductivity of alumina also benefit in offering accuracy in measurements.

Alumina thermocouple protection tubes operate at a temperature range of around 1600 degc. They possess a density of 4 g/cm3 and has fracture toughness value of 5-8. Alumina thermocouple protection tubes also have compressive and breaking strength in the range of 2500 and 400 MPa respectively.

Metal Thermocouple protection tube

Metal protection tubes are also meant for additional shielding for thermocouples. They are either made of stainless steel of alloys that can operate at a temperature of around 1000 degC.

Stainless Steel Thermocouple Protection Tube:

Stainless steel tubes offer higher oxidation resistance. Wherever there requires an emphasis on durability, stainless steel thermocouple tubes are the ideal fit. They offer good corrosion resistance at lesser cost. Stainless steel 熱電対 protection tubes are often used in situations where accuracy is not so critical.

Proper maintenance is crucial while preferring stainless steel protection tubes since they have lesser hardness in comparison with ceramic tubes.

Summarising the above section, the suitability of each type of thermocouple protection tube is a subject of its application. For example, in furnaces environments, where operating temperatures are extremely high refractory-based protections tubes such as Alumina are preferred.

Key Benefits of Thermocouple Protections Tubes

Thermocouple protection tubes find its use in high temperature environments. They act as physical barrier that helps in mitigating contamination. Thermococuple protection tubes also reduces corrosion when the wires are exposed to harsh environments. Some merits are below mentioned.

- Operational life: Thermocouple tubes always protect thermocouple from harsh and corrosive environments that ultimately increases the lifespan of the measuring material. For instance, a thermocouple made of Alumina confers to JIS R1401PT1 standard.

- Extreme accuracy: Thermocouple protection tube functions as insulators that keeps the thermocouple intact to its operational range. Protection tubes also retard the effects of corrosion, contamination and high temperature. As a matter of fact, we can arrive at good accuracy values with the implementation of protection tubes to thermocouples.

- Safety aspects: The accuracy ensured by the thermocouple tubes helps the workmen to control the overheating of system. It also helps minimise equipment damage and entails a rigid safety working condition.

- Structural stability: The tailored design of the protection tube provides great structural stability and impact resistance. This ensures high performance of thermocouple in complex environments that puts extreme stress onto the surface of the material.

- Design consideration: Thermocouple protection tube designs can be adapted depending upon the requirement. The major types are open or closed end or hollow tubes. Open and closed ends are for industries where reading accuracy is preferred. Hollow type ensures protection from corrosion and damage.

Bottom Remarks

The above article highlighted the key aspects and benefits of thermocouple protection tubes. Protection tubes are unavoidable when pondering over the benefits they cater. They ensure lesser corrosion and accurate reading. For ensuring functionality of thermocouple, it is preferred to have it surrounded by the protection tubes of suitable material.