セラミックシャフト

Custom Ceramic Shaft Supplier,Ceramic shafts Manufacturer ;Factory direct supply;Extended use by more than 10%!

Orders now! 10% Discount!

Custom Ceramic Shaft Supplier

ゴージャスなアドバンテージ

Ceramic Shaft Description

GORGEOUS has extensive experience in manufacturing ceramic shafts made of materials such as アルミナ, 酸化ジルコニウム、 そして 窒化シリコン.

Ceramic shafts are essential components for various pump applications, and their application range is wide, including various water pumps and motor equipment.

Ceramic materials have excellent wear resistance and can withstand long-term friction and impact. Compared with traditional metal shafts, ceramic shafts are more durable and are an economical choice for you to save costs!

製造と配送時間の保証

Over 15 years of experience in advanced ceramic production to provide you with high-quality customized production services!

Your goods go through four processes: manufacturing, packaging, loading, and transportation. We serve you carefully and transparently in each process.

陶磁器の製造と輸送は、工程とお客様の所在地によって異なります。お客様のご計画に沿って迅速に製造し、最適な輸送方法を選択いたします。 北米で最速の航空配送、7日以内に到着します。

GORGEOUS は、以下を含む大手物流会社と提携しています。

- MSC(地中海海運会社)

- マールスク

- CMA CGM

- コスコ

- ハパグロイド

- DHL

- UPS

- フェデックス

- TNT

当社は複数の貨物運送業者と提携し、より低価格で効率的な配送オプションを保証します。 時間通りの配達、 そして 隠れた料金はありません!

製造業

パッキング

読み込み中

交通機関

Main Properties of Ceramic Shafts

高硬度

Ceramic materials are harder than traditional metals

耐摩耗性

It can withstand greater friction without being easily worn and has a long service life.

耐腐食性

Not easily corroded by chemicals, and resistant to most acids, alkalis, salts, etc.

耐高温性

It can resist extreme high temperature and is not prone to deformation.

電気絶縁

Excellent electrical insulation, can be used in electrical equipment.

ゴージャスなカスタマイズ可能な製品精度リファレンス

| Shaft Part | Cylindricity can reach 0.003mm |

| Coaxiality can reach 0.002mm | |

| 粗さ 0.02 | |

| Minimum Processing Hole Diameter | Up to 0.3mm, depth limit is 3mm |

| Hole depth accuracy can reach 0.005mm | |

| 粗さ 0.02~0.04 | |

| Plane Machining Tolerance | Parallelism accuracy can reach 0.002 |

| The measurement tolerance is 0.0015mm | |

| Ceramic Thread Machining | Processing internal thread size limit M3.0 |

| Thread accuracy gb-7h | |

| No restrictions on external thread size | |

| Thread accuracy can reach gb-6g |

※具体的な精度は、実際の製品の材質、形状、プロセス要件に応じて決定する必要があります。

Ceramic shaft standard size and specifications

Diameter Range

Micro shaft: 0.5mm - 3mm (commonly used in micro motors)

Conventional shaft: 3mm-20mm (pumps, valves, bearings, etc)

Large shaft: 20mm-50mm or larger (high temperature furnace drive shaft)

Length Range

Short axis: 5mm-50mm (micro motor or sensor)

Medium-long axis: 50mm-300mm (mechanical field)

Extra-long axis: 300mm-1000mm (special equipment)

Examples of Common Diameters

Small diameter: 1mm, 2mm, 3mm, 5mm, 6mm, 8mm

Medium diameter:10mm、12mm、15mm、20mm

Large diameter:25mm、30mm、40mm、50mm

「Support non-standard customization」

「MOQ 1 piece sample order」

Customized Ceramic Shaft Material Parameters and Selection

Guide to Choosing Various Ceramic Materials!

✔️アルミナ: Alumina shaft is the cheapest among many materials, with a very high cost performance. Its density is 3.7-3.92g/cm3 . You can choose 95%, 99%, 99.5%, 99.7% and other purity alumina for customization.

✔️ジルコニア: The density of zirconia shaft is relatively large, exceeding 6.0g/cm3. It has stronger fracture performance than other materials, overcomes the brittleness of ceramics, and it is also self-lubricating, which is very suitable for shaft and pump applications. In addition, you can also choose TTZ, YTZP, ZDY, ZTA and other materials.

✔️Silicon nitride: Silicon nitride shafts are more expensive, but they are lighter and can be polished to a mirror finish of Ra0.05um.

✔️Silicon carbide: The density of silicon carbide shafts is similar to that of silicon nitride, and their hardness is higher than that of general ceramic materials, and their wear resistance is also better.

| アイテム | ユニット | ジルコニアセラミック |

| 密度 | g/cm3 | 6.0 |

| ジルコニア含有量 | % | 94.4 |

| 粒度 | µm | 0.5 |

| ロックウェル硬度(45N) | R45N | 78 |

| ビッカース硬度(荷重500g) | GPa(kg/mm2 ) | 11.5(1175) |

| 曲げ強度(20℃) | MPa | 800 |

| 圧縮強度(20℃) | MPa | 2000 |

| 破壊靭性(20℃) | MPam1/2 | 9.0 |

| 熱伝導率(20℃~400℃) | W /(mk) | 2.5 |

| 熱膨張係数 | 10-6 /℃ | 9.6 |

| 耐熱衝撃性 | △T℃ | 250 |

| 財産 | ユニット | アル2お3 99.7 | アル2お3 99.5 | アル2お3 99 | アル2お3 95 |

| 純度 | — | 99.7% | 99.5% | 99% | 95% |

| 密度 | g/cm3 | 3.92 | 3.9 | 3.8 | 3.7 |

| 曲げ強度 | MPa | 375 | 370 | 340 | 304 |

| 圧縮強度 | MPa | 2450 | 2300 | 2250 | 1910 |

| 弾性係数 | GPa | 380 | 370 | 330 | 330 |

| 破壊靭性 | MPam1/2 | 4.5 | 4.3 | 4.2 | 3.8 |

| 硬度 | HRA | 91 | 91 | 90 | 89 |

| ビッカース硬度 | HV1 | 1600 | 1550 | 1450 | 1400 |

| 熱膨張係数 | 10- 6 K-1 | 7.8 | 7.8 | 7.7 | 7.5 |

| 熱伝導率 | W/mk | 32 | 32 | 25 | 25 |

| 熱衝撃安定性 | △T.℃ | 220 | 220 | 200 | 200 |

| 最大動作温度 | ℃ | 1750 | 1750 | 1700 | 1500 |

| 20℃における体積抵抗 | Ω·cm | 1015 | 1015 | 1014 | 1014 |

| 絶縁強度 | KV/mm | 22 | 20 | 16 | 15 |

| 誘電率(室温) | / | 10 | 11 | 11.5 | 11 |

| MHz誘電損失係数 | tan δ | 1×10-3 | 1×10-3 | 3×10-3 | 3×10-3 |

カスタマイズ可能なセラミックシャフトエンドタイプリファレンス

🔷Straight: can be directly mounted to bearings, bearing seats, brackets, etc.

🔷Keyed: can be precisely combined with your machine to transmit torque to gears, sprockets, etc.

🔷D-Profile: one end is flat and allows insertion into the shaft to firmly install gears, sprockets and bearings, etc.

🔷Splined: can be customized with multiple keyway-like grooves, which can be used in hydraulic systems and machine tools.

🔷With Retaining Ring Grooves: can clamp the retaining ring into the groove, which can be used to separate and locate bearings, rings and sprockets.

🔷Step Down: can use the shoulder near the end of the shaft as a shaft support.

🔷Threaded: the end of the shaft is threaded and can be linked to threaded accessories.

🔷Tapped: has threads inside and can be installed on threaded posts.

🔷Hollow: lighter than solid shafts, can reduce the overall weight of the equipment, can be used for wires, compressed air pipes, etc.

Application of Ceramic Shaft

Ceramic Motor Shaft

Ceramic motor shafts are used in various motor equipment and have a longer life than traditional metal shafts.

Ceramic Shaft for Impeller

Ceramic shaft for impeller, extremely corrosion resistant

Ceramic Shaft for Water Pump

Ceramic shafts for water pumps, used in various water pump equipment, with excellent durability

Engine Ceramic Shaft

Used for various automobile engine shafts, bicycle axles, etc., with strong high temperature resistance.

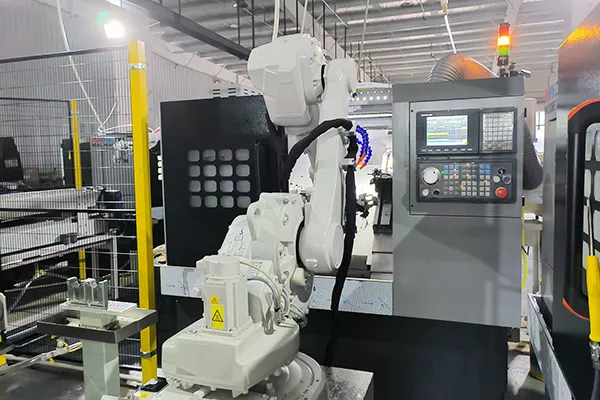

Mechanical Equipment Shaft

Ceramic shafts for various mechanical equipment.

One-stop ceramic shaft manufacturing service

15+ 長年の経験。高精度とOEM設計。プロフェッショナルな研究開発チーム。競争力のある価格。

Ceramic Shaft vs. Metal Shaft

Ceramic shafts have excellent wear resistance and corrosion resistance, especially in some high temperature and corrosive environments.

Metal shafts have better impact and vibration resistance, but are easily corroded and worn.

Ceramic Shaft Manufacturing Process

- Raw material preparation: Select and process suitable ceramic raw materials.

- Molding: Dry pressing, injection molding, etc.

- Drying: Remove moisture after molding and wait for sintering.

- Sintering: High temperature sintering to form a hard ceramic structure.

- Post-processing: Precision machining or other processing.

How to Customize Poducts?

You only need to send us an inquiry and drawings, and our professional team will customize it for you.