Perkenalan

Imagine materials that can resist high heat, pressure, and corrosion. That is what silicon carbide foam does. This material is used in industries ranging from the casting industry to elektronik. This guide will explain what it is, how it works, and why it can solve the most difficult problems of your life.

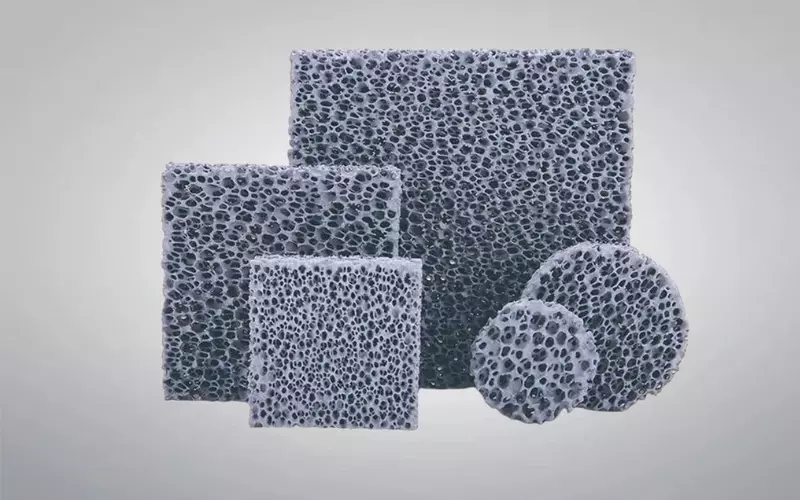

What Is Silicon Carbide Foam

The first step to buying wisely is to know advanced ceramic materials. Silicon carbide foam may sound very technical when you hear about it. It is actually quite easy: a light, porous ceramic that is used to make high-performance industries. You must know what it is and how it works before you pick it.

Material Definition

Silicon carbide foam is a porous substance composed of silicon and carbon. It belongs to the family of advanced ceramic materials, which are known for their hardness and thermal stability.

Moreover, it does not wrap like metals, nor does it melt like plastics, but remains stable at temperatures over 1500 °C. It is used by engineers when they require high thermal resistance and low density.

-

Light in weight and very strong.

-

Customizable for different industries.

-

Best in high heat and corrosive conditions.

I once worked with a manufacturer that faced the problem of frequent casting defects. Replacement with silicon carbide ceramic components immediately increased quality, as this is one of the advanced ceramic materials that is resistant to heat and contamination.

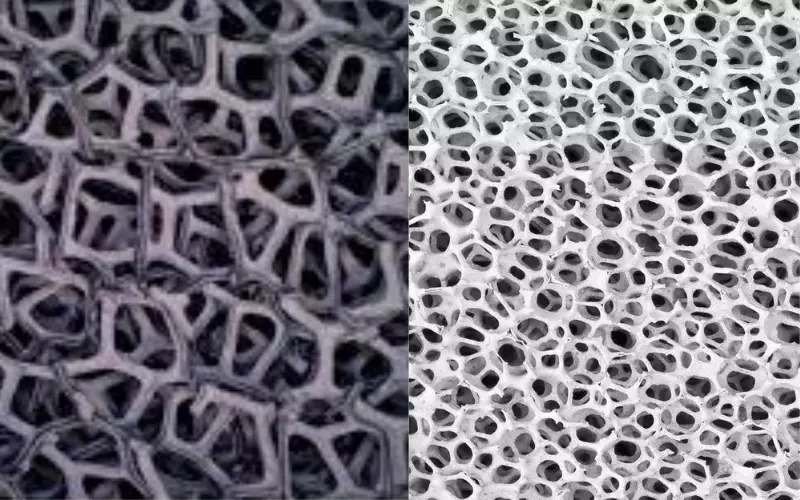

Basic Structure Of Foam Ceramics

Interconnected pores are found in foam ceramics, such as silicon carbide foam. These holes allow gases or liquids to pass through them but filter out undesired particles (impurities).

Imagine a honeycomb that can survive heat in excess of 1400 °C. This is why industries rely on it to provide filters, catalysts, and thermal insulations. It is strong and has a maximum surface area.

-

Strong but lightweight.

-

Used for filtration and insulation.

-

Open-cell design improves flow and filtration

-

Reactions and heat transfer are facilitated by high surface area.

One of the clients presented me with a piece of SiC foam that they used in their laboratory. It seemed weak, but when molten aluminum was poured through it, they were surprised to find it so durable.

Key Properties Of Silicon Carbide Foam

Before purchasing, you need proof of performance. The properties of silicon carbide foam that make it a perfect compound are thermal resistance, mechanical strength, and porosity. Specific industrial problems are solved by each property, which makes it a good advanced ceramic materials for most industries.

Tahanan Termal

Ordinary materials melt under heat, yet silicon carbide ceramic foam does not. It performs well up to 1,500 °C.

Silicon carbide foam can be used in furnaces and engines without melting or warping. It has a thermal resistance exceeding 1500 °C, which is higher than that of metals at high temperatures. This is the reason why foundries use it to deal with molten metals.

-

Resists high operating temperatures.

-

Delivers constant thermal conductivity.

-

Oxidizes slowly even under pressure.

-

Application in foundry and aerospace applications.

I once visited an aerospace workshop where I heard other filters cracking under heat stress. The best part? Only SiC ceramic foam filters survive under repeated thermal cycling.

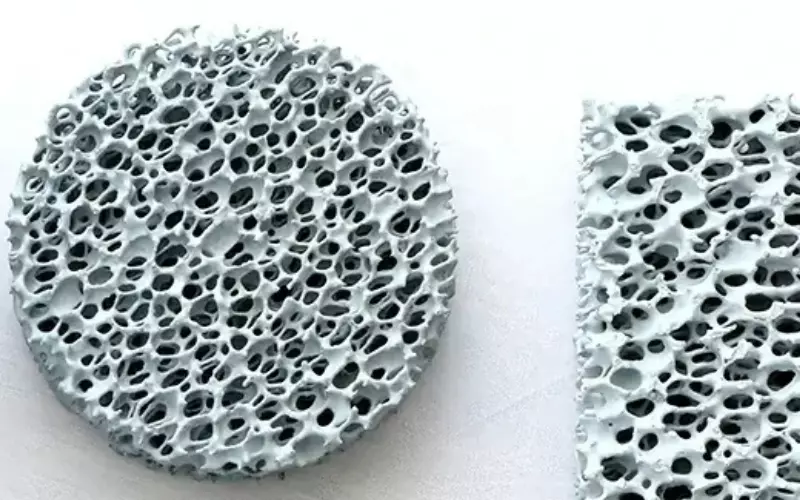

Mechanical Strength and Density

You often need to have a balance between weight and strength. Keramik silikon karbida has both.

Silicon carbide foam is light, yet it provides strength. It is able to change its density with respect to pore size and design. Such a balance allows you to install it in high-pressure or high-vibration areas without breaking it. This longevity can be translated into long life and reliability in otomotif brake systems.

-

Density ranges from 0.3 to 0.8 g/cm³

-

Retains compressive and flexural strength.

-

Constant under action works without deformation.

-

High operating life in harsh conditions.

In one foundry, the workers informed me that they would change filters every few pours. Replacement time and money were saved after switching to SiC foam filters, which decreased by half.

Porosity and Surface Area

Porosity defines performance. SiC foam may be porous to 90 %. It is useful in filtration and catalytic reactions.

The secret weapon of silicon carbide ceramic foam is porosity. The large surface area promotes chemical reaction and filtration. In case you are working with catalytic converters, using this foam permits the maximum contact between gases and active materials. The more contact, means more efficiency and the cleaner the output.

-

Gas and liquid flow through high porosity.

-

Chemical reactions take place on the surface.

-

Lessens casting blockages.

-

Enhances the productivity of catalyst converters.

At a chemical plant, an engineer explained that foam ceramics made the reaction more efficient by increasing surface contact between the catalyst and the reactants. It may seem technical, but the outcome was a simple outcome, more yields and less loss.

Comparison of Properties That Matter Most

|

Milik |

Value / Description |

Mengapa Hal Ini Penting |

|

Kepadatan |

0.25–0.6 g/cm³ |

Light yet strong for aerospace and automotive |

|

Stabilitas Termal |

>1500°C |

Withstands extreme heat cycles |

|

Tahan Korosi |

Acid/alkali resistant |

|

|

Kekuatan Mekanik |

High compressive strength |

Durable in engines and reactors |

|

Porositas |

60–90% |

Ideal for filters and catalysts |

Industrial Applications Of Silicon Carbide Foam

Now that you know the properties, let us see where silicon carbide foam is applied. It is used in solving industry issues from foundries to kedirgantaraan.

Casting and Foundry Filters

To enhance the quality of molten metal, foundries use ceramic filters. In foundries, the quality of products is compromised by impurities in the molten metal. Those particles are caught in a SiC ceramic foam filter.

-

Holds impurities but does not prevent the flow.

-

Improves cast surface finish.

-

Minimizes porosity of metals.

-

Cuts, rework, and scrap rates.

Dirgantara dan Otomotif

Weight and durability are important in transport industries. Silicon carbide foam offers both. Plane and car engines require advanced ceramic materials with heat and pressure resistance. You may not notice, but every sound departure or long ride relies on materials like this.

-

Used in thermal protection in spacecraft.

-

Helps engines resist wear and heat.

-

Enhances car fuel efficiency.

-

Improves braking systems safety.

I once witnessed an aerospace technician telling me how they were able to reduce weight by using SiC foam thermal shields without risking the safety margins.

Electronics and Catalytic Uses

Electronics require heat control, and catalysts require surface. Silicon carbide foam offers both. Ceramic foam is used to insulate and to avoid overheating. Its high surface area accelerates reactions in the catalytic system.

-

Used as thermal sinks and thermal insulators.

-

Reduces thermal stress in microelectronics.

-

Serves as a catalytic reactant.

-

Removes automotive exhaust gases.

One of my colleagues in an electronics plant informed me that silicon carbide ceramic foam had been used to increase the life of their heat-sensitive equipment by several months and save thousands of replacements.

How SiC Ceramic Foam Filters Work

Filters are not as easy as they may sound to work. SiC ceramic foam filters operate based on the principle of tortuous flow path.

A SiC foam filter is achieved by pushing molten metal through a porous framework. Unwanted particles are caught as the liquid flows. You know, when you invest in SiC ceramic foam filters, you have a guarantee of a better casting and a reduction in defects.

-

Contaminants are attached to the walls of pores.

-

Clean metal flows through

-

Surface finish improves

-

Casting strength increases

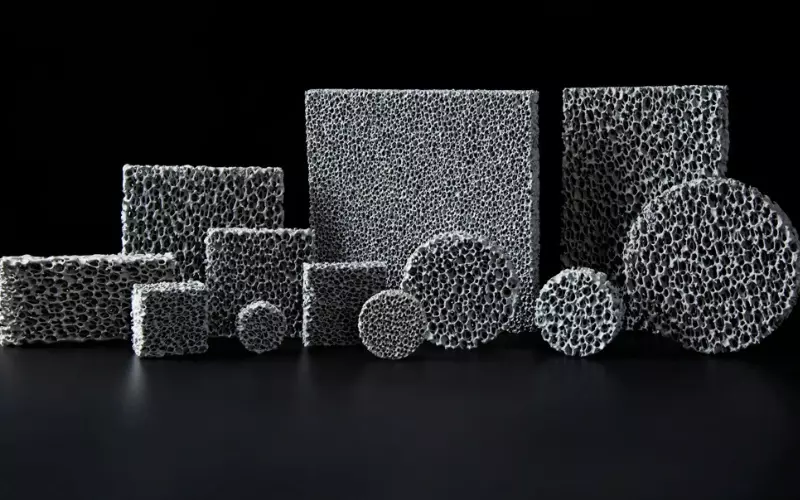

Buyer’s Checklist For SiC Foam Filters

Check this list before you make your final purchase. The points seem to be straightforward, but the failure to consider each of them can result in downtime, increased expenses, or high product quality.

-

Pore Size (PPI): The bigger the PPI (pores per inch), the finer the filtration, which is desired when it comes to small impurities. But the lower PPI is easier to flow and can be applied to larger castings. Never confuse the PPI and the kind of metal you are using.

-

Kepadatan: The flow rate, as well as mechanical strength, depends on the density of the filter. Too thick and you stand the chance of slower pouring. Too deep, and the filter could burst. Striking the right balance in your process.

-

Thermal Rating: Each SiC foam filter has a temperature range it can tolerate. Ensure that the thermal rating is suitable for your molten metal setting or that it will crack or even fail during pouring.

-

Supplier Reputation: Do not roll the dice with suppliers. An established brand or a manufacturer that has some references in the industry will mean that you will have filters that have been tested in terms of performance and stability.

-

Kustomisasi: Does your application require specific sizes, shapes, or drawings? Check with your supplier that they can be customized. Ready-made filters do not fit all casting systems.

Why Choose GORGEOUS For Silicon Foam Ceramics

With silicon carbide foam filters, precision and consistency are more important than anything. That’s why we use cutting-edge technology and decades of experience at GORGEOUS to produce the best filters in the industry. This is why buyers and engineers love us:

-

Tailored Pore Structures: We can produce SiC foam filters that have a high pore size distribution (10-30 PPI) to achieve the appropriate balance between flow rate and filtration efficiency for your casting needs.

-

High Thermal Shock Resistance: Our filters resist repeated heating and cooling, so they work with steel, iron, and non-ferrous alloy casting.

-

Consistent Open-Cell Network: GORGEOUS uses advanced cetakan Dan sintering techniques to form uniform pore channels. This lowers turbulence in the flow of metals and minimizes trapped gas or inclusions.

-

Large-Scale Casting Support: We provide both small precision parts and large industrial castings filters with a production capacity of three plants

-

Industry-Specific Customization: We modify density, porosity, and filter size to fulfill the interests of aerospace foundries, automotive casting lines, and electronics manufacturing.

Kesimpulan

Silicon carbide foam provides durability, heat resistance, and filtration power. It helps in many industries, from foundry to aerospace. When you make decisions on suppliers whom you trust, you can be assured of reliability and efficiency in your operations.

Ready to upgrade your operations with advanced ceramic materials? Collaborate with GORGEOUS for silicon carbide foam with cleaner output, performance, and reliability.

Tanya Jawab Umum

What is silicon carbide foam used for?

It will be used in casting, aerospace, automotive, and electronic filtration.

Can SiC foam filters handle molten steel?

Yes, they can, with heat resistance up to 1500 °C.

Can you customize pore sizes?

Yes, mostly suppliers can adjust porosity size to suit your requirements.