مقدمة

كربيد السيليكون (SiC) is a well-known ceramic material that is very useful to modern-day technology. The truth is that many emerging industries today that demand high temperatures and thermal stability in intense working conditions can barely do without silicon carbide. The reason for this is not far-fetched – silicon carbide possesses the much-needed properties that make it perform brilliantly under these circumstances. Chief of them is the super hardness and high thermal conductivity of this trending ceramic material. In today’s article, you will learn more about silicon carbide’s properties and how useful they are to new energy and emerging industries worldwide. You will also see why SiC benefits semiconductors and the power electronics industry.

What is Silicon Carbide?

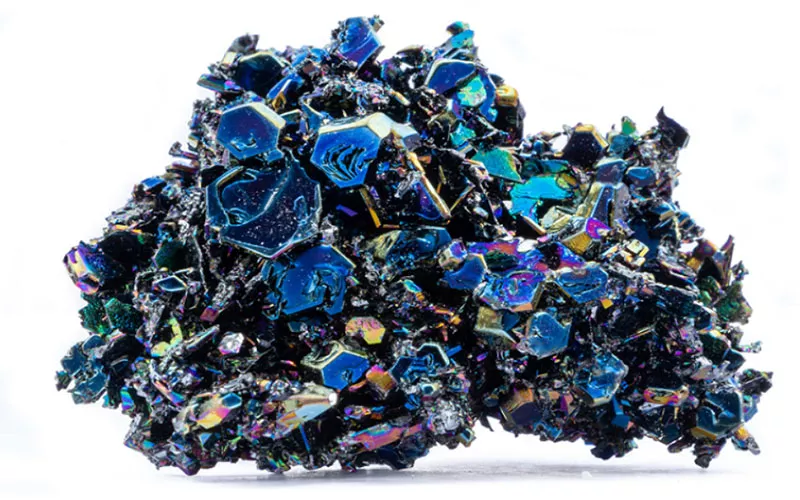

Silicon carbide (SiC) is a greyish crystalline ceramic material made industrially from silicon and carbon. Silicon carbide has crystal lattice tetrahedral structures of carbon and silicon covalently bonded to make it extremely hard. Most manufacturers call it Carborundum and it’s very relevant today due to its high performance standards and properties. Above any other advanced ceramic material, silicon carbide is a major component of the third-generation semiconductors you see today. Without it, most of these semiconductors won’t function properly. They would either break under heavy load and tension or overheat in intense temperatures because of poor heat dissipation.

Silicon carbide is actually easy to produce using the Acheson process. All you need to do is, mix excess silicon (petroleum quartz), alongside some essential additives with carbon (industrial coke) in a furnace with extremely high heat and temperatures reaching 2,400°C. If you are a manufacturer looking to produce the best grades of SiC for high-profile applications, you can go further to sinter the silicon carbide under more intense temperatures and lesser pressure.

So, what is silicon carbide used for? In reality, the uses of SiC are numerous and cut across many sectors. Silicon carbide is one of the few advanced ceramic materials that can significantly improve the efficiency and performance of any of your devices or industrial equipment. As a production engineer, it can help you produce faster and more stable devices- devices that are not just immune to overheating but lightweight, which can greatly reduce your production cost.

You can use silicon carbide to produce safer and better batteries for electric vehicles because of their lightweight and thermal stability. These silicon carbide batteries tend to charge at a faster rate not only in electric vehicles but in other high-power electronic devices. Automotive companies, and recently the aerospace industry now use SiC materials to produce spare parts, engine bearings, and seal rings due to their super-hard wear-resistant nature.

You can also use it to produce silicon carbide chips and sic wafers for high-grade semiconductors, wear-resistant grinding and cutting tools/wheels, furnace linings, optical instruments, mirrors, medical devices like X-rays and a host of other essential components used in new industries today.

خصائص كربيد السيليكون

Some of the outstanding properties of SiC are:

-

It’s insoluble in water and acids

-

It has a high compressive strength and fracture toughness of 6.8 MPa·√m

-

It possesses a density of 3.21 g/cm 3

-

It has a hardness of 32 GPa and a rating of 9.5 on the Mohs Hardness Scale

-

It’s a wide bandgap semiconductor with a bandgap of 3.26 eV

-

It possesses a thermal conductivity of 120 W/m•K

-

It has an elastic modulus of 440 GPa

-

It has a flexural strength of 490 MPa

-

It can withstand temperatures reaching 2,600°C

-

The coefficient of thermal expansion is 4.0 x10–6/°C

-

It’s highly resistant to corrosion, wear and tear.

Silicon Carbide and Semiconductors

Before now, several industries used silicon chips and some other advanced ceramic materials to manufacture semiconductors for electronic devices and machines. You can call these semiconductors they used, “first-generation semiconductors” due to their slow speed and overheating. However, because they were not wide bandgap semiconductors, their overall efficiency was poor, especially with increased demand for high precision in heated temperatures. Fast-forward to today, silicon carbide usage in these same industries has now led to the production of better, much improved wide bandgap semiconductors. These semiconductors now known as “third-generation semiconductors” contain silicon carbide chips and SiC wafers.

Emerging industries use silicon carbide substrates (chips and wafers) to boost the performance standards of these newly produced wide bandgap semiconductors. The silicon carbide chips and heat sinks in the semiconductors and electronic panels of power devices help them dissipate heat faster. It also makes them tough enough to withstand tension or overload without breaking. All these are possible because of SiC’s hardness and high thermal conductivity.

Today, engineers still prefer silicon carbide-based semiconductors to silicon in their production. Why? They’ve got a low cost of production, and compared to the others, they don’t overheat or break down in high temperatures, highly mechanical, and high-stress environmental conditions. These merits are due to their excellent thermal stability and hardness.

The efficiency of these SiC materials in semiconductors can even be improved upon when you dope them. Some dopants include boron, aluminum, arsenic, phosphorus, etc.

So, if not silicon carbide, what other better material would you as a manufacturer consider in producing and coating these semiconductors? None! Let’s move a bit further into silicon carbide usage in emerging industries.

Silicon Carbide and Emerging Industries

A lot of manufacturing industries that started off in the last few years all use silicon carbide in high-precision applications. Industries in various fields like engineering, automobiles, power electronics, solar energy, aerospace, abrasives, and even more recently, healthcare. These industries all need a very stable and tough ceramic material with excellent properties such as the ones SiC provides. For example, mechanical engineering firms need high-strength materials to produce rods, kiln furnace linings, machine rotors, and seal rings. The best material for these applications is SiC because only Diamond beats it when it comes to hardness and thermal stability.

Automotive industries know their car spare parts and engines would function better with silicon carbide. How? SiC is very hard as we previously mentioned; it’s also very resistant to wear, and rust-causing chemicals and stable enough to conduct both heat and electricity without causing external issues. These are very essential qualities if you are to produce good cars with excellent parts and functionality.

With new automotive industries now venturing into the production of electric vehicles like Tesla, they need SiC to improve the power conversion rates, produce silicon carbide batteries, reduce the size, and maintain stable acceleration and deceleration while driving.

Solar energy is not left out, emerging industries in this field now produce silicon carbide-based solar inverters and batteries with high efficiency and power modules. Uninterrupted power supply (UPS) devices and wind turbines used in renewable energy are all part of silicon carbide usage. Silicon carbide helps you reduce material cost and size while increasing the effectiveness of these solar products. Solar conversion rates now get up to at least 95% due to silicon carbide usage. At 97.5%, these improved inverters have reduced overall energy loss equivalent to 25%. You can imagine the great advantages SiC offers here.

Moving on, power electronics also utilize SiC in the production of more efficient and power-saving LED lights. With a reduced temperature loss and better electricity conductivity, SiC tends to make these LED lights last longer and even display brighter. This amounts to a reduction in the cost of production and better outputs for industries in this field.

Research has recently shown that silicon carbide usage and applications in all these emerging industries have skyrocketed globally. At its increasing rate, the current SiC market (for both semiconductors, power electronics, and other applications) valued at $4 billion in 2023, could reach a market high of over $10 billion by 2026.

Investors in new energy and ceramics are buying into it at an astonishing rate. Silicon carbide suppliers are now so rampant across various continents of the world because of SiC’s brilliant potential. Don’t be left out, contact us now at GGS سيراميك for top-quality SiC and Sintered SiC materials that suit your applications. We are frontrunners among silicon carbide suppliers, and you can rest assured that you will get the best from us.

الأسئلة الشائعة

What is silicon carbide used for?

Aside from silicon carbide usage in highly mechanical and high-stress environmental conditions, most manufacturers use it as an abrasive for producing sandpaper, grinding, or cutting tools and wheels.

What are the raw materials in silicon carbide production?

The main raw materials used in SiC production (through the Acheson process) are petroleum quartz (industrial silicon) and coke (carbon).

What is the melting point of silicon carbide?

Silicon carbide doesn’t have a fixed melting point. However, you’ll notice that it begins to sublimate at 2,730°C.

خاتمة

Now, you certainly know the best answers to “What is silicon carbide used for?” So, if you’re a first-timer or have been in the industry, you know for a fact that silicon carbide is the best way to go. This multi-dimensional ceramic material is highly used in semiconductors, power electronics, and several other fields. Aside from being so hard and thermally stable, its ability to effortlessly resist dangerous chemicals, high temperatures, and wear and tear in harsh conditions makes it an excellent material for any manufacturer to rely on. Silicon carbide deserves all the popularity and recognition it’s getting globally today. Without any doubt, it provides a strong ray of hope for emerging industries now and in the future!