عمود سيراميك

Custom Ceramic Shaft Supplier,Ceramic shafts Manufacturer ;Factory direct supply;Extended use by more than 10%!

Orders now! 10% Discount!

Custom Ceramic Shaft Supplier

ميزة رائعة

Ceramic Shaft Description

GORGEOUS has extensive experience in manufacturing ceramic shafts made of materials such as الألومينا, أكسيد الزركونيوم، و نتريد السيليكون.

Ceramic shafts are essential components for various pump applications, and their application range is wide, including various water pumps and motor equipment.

Ceramic materials have excellent wear resistance and can withstand long-term friction and impact. Compared with traditional metal shafts, ceramic shafts are more durable and are an economical choice for you to save costs!

ضمان وقت التصنيع والشحن

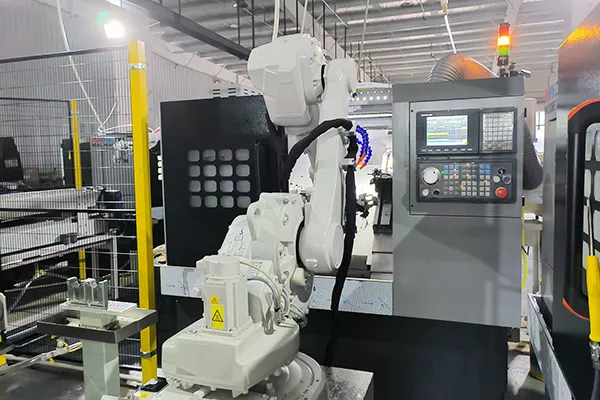

Over 15 years of experience in advanced ceramic production to provide you with high-quality customized production services!

Your goods go through four processes: manufacturing, packaging, loading, and transportation. We serve you carefully and transparently in each process.

تتأثر عملية تصنيع ونقل السيراميك بعملية التصنيع وموقعكم. سنصنعها لكم بسرعة وفقًا لخطتكم، ونختار لكم أفضل طريقة نقل. أسرع تسليم جوي في أمريكا الشمالية، يصل خلال 7 أيام.

تختار شركة GORGEOUS التعاون مع العديد من شركات الخدمات اللوجستية الرائدة، بما في ذلك:

- شركة الشحن المتوسطي (MSC)

- ميرسك

- سي ام ايه سي جي ام

- كوسكو

- هاباج لويد

- دي اتش ال

- يو بي إس

- فيديكس

- تي ان تي

نحن نعمل مع العديد من شركات الشحن لضمان خيارات شحن فعالة بأسعار أقل، التسليم في الوقت المحدد، و لا توجد رسوم خفية!

تصنيع

التعبئة والتغليف

تحميل

مواصلات

Main Properties of Ceramic Shafts

صلابة عالية

Ceramic materials are harder than traditional metals

مقاومة للتآكل

It can withstand greater friction without being easily worn and has a long service life.

مقاومة للتآكل

Not easily corroded by chemicals, and resistant to most acids, alkalis, salts, etc.

مقاومة درجات الحرارة العالية

It can resist extreme high temperature and is not prone to deformation.

العزل الكهربائي

Excellent electrical insulation, can be used in electrical equipment.

مرجع دقة المنتج القابل للتخصيص الرائع

| Shaft Part | Cylindricity can reach 0.003mm |

| Coaxiality can reach 0.002mm | |

| خشونة 0.02 | |

| Minimum Processing Hole Diameter | Up to 0.3mm, depth limit is 3mm |

| Hole depth accuracy can reach 0.005mm | |

| خشونة 0.02~0.04 | |

| Plane Machining Tolerance | Parallelism accuracy can reach 0.002 |

| The measurement tolerance is 0.0015mm | |

| Ceramic Thread Machining | Processing internal thread size limit M3.0 |

| Thread accuracy gb-7h | |

| No restrictions on external thread size | |

| Thread accuracy can reach gb-6g |

*يجب تحديد الدقة المحددة وفقًا لمتطلبات مادة المنتج الفعلية والشكل والعملية.

Ceramic shaft standard size and specifications

Diameter Range

Micro shaft: 0.5mm - 3mm (commonly used in micro motors)

Conventional shaft: 3mm-20mm (pumps, valves, bearings, etc)

Large shaft: 20mm-50mm or larger (high temperature furnace drive shaft)

Length Range

Short axis: 5mm-50mm (micro motor or sensor)

Medium-long axis: 50mm-300mm (mechanical field)

Extra-long axis: 300mm-1000mm (special equipment)

Examples of Common Diameters

Small diameter: 1mm, 2mm, 3mm, 5mm, 6mm, 8mm

Medium diameter:10mm、12mm、15mm、20mm

Large diameter:25mm、30mm、40mm、50mm

「Support non-standard customization」

「MOQ 1 piece sample order」

Customized Ceramic Shaft Material Parameters and Selection

Guide to Choosing Various Ceramic Materials!

✔️الألومينا: Alumina shaft is the cheapest among many materials, with a very high cost performance. Its density is 3.7-3.92g/cm3 . You can choose 95%, 99%, 99.5%, 99.7% and other purity alumina for customization.

✔️Zirconia: The density of zirconia shaft is relatively large, exceeding 6.0g/cm3. It has stronger fracture performance than other materials, overcomes the brittleness of ceramics, and it is also self-lubricating, which is very suitable for shaft and pump applications. In addition, you can also choose TTZ, YTZP, ZDY, ZTA and other materials.

✔️Silicon nitride: Silicon nitride shafts are more expensive, but they are lighter and can be polished to a mirror finish of Ra0.05um.

✔️Silicon carbide: The density of silicon carbide shafts is similar to that of silicon nitride, and their hardness is higher than that of general ceramic materials, and their wear resistance is also better.

| غرض | وحدة | سيراميك الزركونيا |

| كثافة | جم/سم3 | 6.0 |

| محتوى الزركونيا | % | 94.4 |

| حجم الحبوب | ميكرومتر | 0.5 |

| صلابة روكويل (45 نيوتن) | R45N | 78 |

| صلابة فيكرز (حمل 500 جرام) | جيجا باسكال (كجم/مم)2 ) | 11.5 (1175) |

| قوة الانحناء (20 درجة مئوية) | ميجا باسكال | 800 |

| قوة الضغط (20 درجة مئوية) | ميجا باسكال | 2000 |

| صلابة الكسر (20 درجة مئوية) | إم بي إيه إم1/2 | 9.0 |

| الموصلية الحرارية (20 درجة مئوية - 400 درجة مئوية) | و / (مك) | 2.5 |

| معامل التمدد الحراري | 10-6 /درجة مئوية | 9.6 |

| مقاومة الصدمات الحرارية | △درجة مئوية | 250 |

| ملكية | وحدة | ال2ا3 99.7 | ال2ا3 99.5 | ال2ا3 99 | ال2ا3 95 |

| نقاء | — | 99.7% | 99.5% | 99% | 95% |

| كثافة | جم/سم3 | 3.92 | 3.9 | 3.8 | 3.7 |

| قوة الانحناء | ميجا باسكال | 375 | 370 | 340 | 304 |

| قوة الضغط | ميجا باسكال | 2450 | 2300 | 2250 | 1910 |

| معامل المرونة | المعدل التراكمي | 380 | 370 | 330 | 330 |

| صلابة الكسر | إم بي إيه إم1/2 | 4.5 | 4.3 | 4.2 | 3.8 |

| صلابة | إدارة الموارد البشرية | 91 | 91 | 90 | 89 |

| صلابة فيكرز | HV1 | 1600 | 1550 | 1450 | 1400 |

| معامل التمدد الحراري | 10- 6 ك-1 | 7.8 | 7.8 | 7.7 | 7.5 |

| الموصلية الحرارية | وات/مك | 32 | 32 | 25 | 25 |

| استقرار الصدمة الحرارية | △T.℃ | 220 | 220 | 200 | 200 |

| أقصى درجة حرارة تشغيل | درجة مئوية | 1750 | 1750 | 1700 | 1500 |

| مقاومة الحجم عند 20 درجة مئوية | أوم·سم | 1015 | 1015 | 1014 | 1014 |

| القوة العازلة | كيلو فولت/مم | 22 | 20 | 16 | 15 |

| ثابت العزل الكهربائي (درجة حرارة الغرفة) | / | 10 | 11 | 11.5 | 11 |

| عامل فقدان العازل ميغاهيرتز | تان δ | 1×10-3 | 1×10-3 | 3×10-3 | 3×10-3 |

نوع مرجعي لنهاية عمود السيراميك القابل للتخصيص

🔷Straight: can be directly mounted to bearings, bearing seats, brackets, etc.

🔷Keyed: can be precisely combined with your machine to transmit torque to gears, sprockets, etc.

🔷D-Profile: one end is flat and allows insertion into the shaft to firmly install gears, sprockets and bearings, etc.

🔷Splined: can be customized with multiple keyway-like grooves, which can be used in hydraulic systems and machine tools.

🔷With Retaining Ring Grooves: can clamp the retaining ring into the groove, which can be used to separate and locate bearings, rings and sprockets.

🔷Step Down: can use the shoulder near the end of the shaft as a shaft support.

🔷Threaded: the end of the shaft is threaded and can be linked to threaded accessories.

🔷Tapped: has threads inside and can be installed on threaded posts.

🔷Hollow: lighter than solid shafts, can reduce the overall weight of the equipment, can be used for wires, compressed air pipes, etc.

Application of Ceramic Shaft

Ceramic Motor Shaft

Ceramic motor shafts are used in various motor equipment and have a longer life than traditional metal shafts.

Ceramic Shaft for Impeller

Ceramic shaft for impeller, extremely corrosion resistant

Ceramic Shaft for Water Pump

Ceramic shafts for water pumps, used in various water pump equipment, with excellent durability

Engine Ceramic Shaft

Used for various automobile engine shafts, bicycle axles, etc., with strong high temperature resistance.

Mechanical Equipment Shaft

Ceramic shafts for various mechanical equipment.

One-stop ceramic shaft manufacturing service

15+ سنوات من الخبرة. دقة عالية وتصميم OEM. فريق بحث وتطوير محترف. أسعار تنافسية.

Ceramic Shaft vs. Metal Shaft

Ceramic shafts have excellent wear resistance and corrosion resistance, especially in some high temperature and corrosive environments.

Metal shafts have better impact and vibration resistance, but are easily corroded and worn.

Ceramic Shaft Manufacturing Process

- Raw material preparation: Select and process suitable ceramic raw materials.

- Molding: Dry pressing, injection molding, etc.

- Drying: Remove moisture after molding and wait for sintering.

- Sintering: High temperature sintering to form a hard ceramic structure.

- Post-processing: Precision machining or other processing.

How to Customize Poducts?

You only need to send us an inquiry and drawings, and our professional team will customize it for you.