مقدمة: Oxygen sensors are instruments that communicate information by analyzing the gases resultant from automobile and industrial smoke emissions. There are various types of O2 sensors. These range from those found in automotive catalytic analyzers and Industrial oxygen analyzers.

FIG 1: An automotive oxygen sensor

Oxygen sensors operate effectively at 650°C, making them ideal for high-temperature applications. You are advised to choose sensors which have a response time of under 10 seconds and a lifespan of up to 10 years in clean conditions.

Whether you are optimizing combustion in a power plant or ensuring safety in chemical processing, zirconia-based oxygen sensors are essential tools. But beyond the technical specialties, what really matters is how these sensors fit into your business, and where you source them.

You also need to consider their cost and how they impact your purpose.

This article highlights the basics and practical considerations for buyers who want to invest in high-quality zirconia oxygen sensors.

Zirconium is an advanced ceramic and is a semiconductor material used for producing jewellery, abrasives, fire-resistant materials, as well as glaze for porcelain products, Stabilized Zirconia oxide serves as a Thermal Barrier Coating (TBC) for high thermal machinery.

Zirconium substrates are excellent choices as ceramic coating of substances.

Items that are coated with zirconium oxide are incorporated with the distinct features of durability, strength, ability to withstand wear and tear as well as resistance to corrosion.

However, just like every other industrial product, there is fear that ceramic coatings on materials will wear off, after long usage. It is in order to reduce incidence of peeling and worn-out in these materials that it becomes necessary to stabilize zirconia.

FIG 2: A Zirconia Blade

Stabilization of zirconia oxide is done, in order to maximize the use of the excellent properties of this advanced ceramic material. Unstabilized zirconia O2 is unreliable for use because it does not exist in one single phase. Zirconium oxide exhibits three transient phases of being monoclinic, tetragonal and cubic crystal structures.

The most trusted feature of zirconium oxide which is required for use in oxygen analyzers, is its cubic phase. The stabilization process therefore transforms zirconium oxide to the usable form, which is the cubic crystalline structure.

How zirconia is stabilized

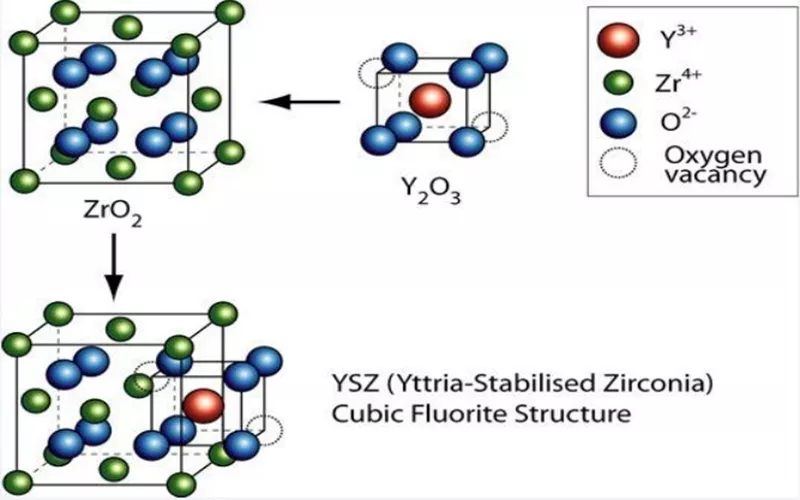

Stabilization of zirconium oxide is facilitated by the combination of zirconium oxide substrate with Yttrium. Yttrium acts as an alloy to zirconium oxide. Alloys result from the combination of either metallic or non-metallic ions, to give them improved qualities.Yttrium replaces some ions in the Zirconium oxide.

Combination of Zirconium Oxide and Yttrium yields YSZ which is Yitria stabilized Zirconia. At this level, zirconia oxide is fortified and transformed into a higher advanced ceramic material, with the ability to withstand higher temperatures, corrosion and wear and tear which is due to prolonged usage.

Attributes of Yttria stabilized zirconia

Stabilized Zirconia Oxide is structurally strong. This is because the Yttrium with which Zirconium O2 was combined is strong. This makes the substance tough and valuable for cutting difficult metals.They are capable of withstanding high temperature conditions. It conducts oxygen very effectively, is resistant to corrosion by certain acids and salts.

FIG 3: Physical structure of Yttria-stabilized zirconia

Stabilized Zirconium O2 is very strong. Zirconium Oxide retains its advanced ceramic properties which are inbuilt, which informs its choice as a material for coating. However, additional strength is brought about by the stabilization process.

When زركونيا مثبتة باليتريا is used under very extreme temperature conditions, it is able to withstand wear and tear. This is why it suits very well for the manufacture of oxygen sensors located in automobile exhaust. In spite of frequent use and also in cases where the fuel used is not optimized for combustion, it protects your engines from damage.

For example, engines of aeroplanes and gas turbines are coated with ceramic substances that help them withstand pressure and corrosion. However, prolonged use of these ceramic coated machinery results in wear and tear. Stabilized Zirconia coatings combine toughness, low thermal conductivity, resistance to corrosion with sintering, to preserve machines.

Stabilized zirconia is often combined with yttria or magnesia to enhance its ionic conductivity. It acts as a solid electrolyte in oxygen sensors. At high temperatures, it allows oxygen ions to migrate, generating a voltage signal that corresponds to oxygen levels in the surrounding gas.

This principle which is rooted in electrochemistry, has been refined over decades for industrial use.

This is how a zirconia oxygen sensor works. Two porous platinum electrodes sandwich a layer of stabilized zirconia. One side is exposed to a reference gas (usually air), while the other faces the sample gas. The difference in oxygen partial pressure creates an electromotive force, following the Nernst equation, which translates to a measurable voltage.

The voltage ranges from 0 to 1.2 volts, depending on the oxygen concentration. This voltage is stable and linear for industrial models, which makes it easy to integrate them into control systems.

1.Titania oxygen sensor: This is also known as the Lambda sensor. It does not generate its own voltage. Instead, Titanium oxygen sensor initiates electrical resistance, in relation to the oxygen being circulated inside the exhaust pipe of an automotive machine. Detection of O2 gas by this device is independent of atmospheric air.

This sensor uses Titanium Oxide to send signals to the Engine Control Unit (ECU), and to warn of any abnormalities in the automotive’s combustion system, The ECU on receiving the signal, adjusts the ratio of the air to fuel, to the correct measurement.

Care should be taken in the use of a Titanium Oxide sensor, as it is prone to wear and tear. Sources of degradation of Titanium Oxide sensor include faulty connection of wires and circuits, accidental physical damage, as well as contact with contaminated oil.

2. Wideband oxygen sensor accurately tunes fuel delivery systems and gives accurate estimation of fuel to air ratio of the engine. This sensor enables exact determination of ratio of fuel to air, during major gear manoeuvres such as acceleration. It is made up of a pump cell, reference air chamber, nernst cell and heater element.

The air chamber serves as a reference point to measure oxygen levels against ambient air. The pump cell determines concentration of oxygen in the air passed through the pumping current. The nernst cell measures the difference in oxygen levels between the exhaust and ambient air, while the heater element regulates the sensor’s temperature.

FIG. 4: A wideband oxygen analyzer.

3. Narrowband oxygen sensor uses zirconium dioxide to provoke heat, when different oxygen levels are exposed to it. It monitors exhaust composition to reduce dangerous emissions from your car. This ensures that the car engine has efficient combustion to keep the catalytic converter in good health.

The Narrowband oxygen sensor is fitted in the exhaust of an automobile. It has a two-sided feature. One side faces the outside air for reference, while the other side faces the exhaust compartment. It is more affordable and commonly used than other types of oxygen sensors. However, it is not as energy-saving as wideband oxygen sensors.

FIG 5: Oxygen Sensor fitted in an automobile engine.

4. Heated oxygen sensor measures temperature of a system or space, used in industrial, automotive and consumer applications. It is also known as thermocouple, and measures the amount of atomic activity inside an object. When there is no feeling of hotness in an object, we can assume that there is no atomic activity within the object.

As soon as heat is applied, atoms start moving in the object and we get what we know as heat sensation. Heat emitted by an object is also known as its infrared signature. That is why infrared glasses are fitted in night vision goggles to help us see in the dark

5. Planar oxygen sensor has low profile design and density, and is used to monitor responses of leaves to light or dark scenarios, during photosynthesis. It is typically used for biological experiments.

6. Zirconia oxygen sensor: Zirconia is a metallic element used in the advanced ceramic industry to produce durable and long lasting materials. When zirconium is combined with oxygen, the result is Zirconium oxide otherwise known as Zirconium dioxide, which takes the chemical form of ZrO2.

Industrial Applications of Zirconia Sensors

In the world of industrial gas monitoring, few materials have proven as reliable and versatile as stabilized zirconia. This ceramic compound forms the backbone of many oxygen sensors, enabling precise measurements in harsh environments where accuracy can make or break operations.

FIG. 6: An Industrial Oxygen Analyzer

Stabilized zirconia oxygen sensors are most reliable for monitoring O2 levels in exhaust gases, boilers, and furnaces in industrial settings. Power plants use them to fine-tune combustion, reducing fuel waste and emissions. In the oil and gas industry, they are used for flare stack monitoring.

Chemical manufacturing relies on these sensors for process control in reactors, where precise oxygen analysis prevents explosions or inefficiencies. Biomass and waste-to-energy facilities benefit too, as zirconia oxygen analysers handle dirty, high-particulate environments without frequent replacements.

Automotive testing labs also use them for emissions analysis. However in the real sense, actual patronage comes from the heavy duty industry. Zirconia O2 analyzers are very important for continuous oxygen monitoring. For specialized needs, high temperature variants withstand up to 1,7000C, making them perfect for melting or metal processing.

FIG 7: Oxygen analyzer in a testing laboratory

The Market Push for Zirconium Oxygen Sensors

The push for energy efficiency as well as enforcement of stricter standards for gas emission, has increased demand for zirconium oxygen sensor. The market was valued at about $1.5 million in the year 2024. Market value is projected to rise to or above $2.5 billion in the 2033. These estimates are made at a Compound Growth Rate (CAGR) of 6.5%.

FIG 8: Spacecraft built with Thermal Barrier Coating

Conclusion: Whether you are a zirconia oxygen sensor manufacturer, a car owner or a mechanic, this article is for you. At ggsceramics, we offer precise and high quality materials. Our products integrate seamlessly with your systems. Visit us today and get your zirconium ceramic at excellent and affordable prices.