你的 氧化铝研磨球 offer high hardness, high temperature and chemical resistance, insulation, high purity and low lifecycle costs. These 氧化铝球 properties outperform steel in your fine grinding, milling, chemical and electronics industries.

What Are Alumina Balls

-

Alumina balls are spherical ceramics made from purity >= 99.99% 氧化铝(Al₂O₃).

-

Your alumina ceramic balls deliver exceptional hardness, stability and corrosion resistance, with no contamination.

3. Alumina Ceramic Ball Properties (And Benefits)

3.1 Extremely Hard and Resistant to Wear

-

With a hardness of 9 on the 莫氏硬度, your alumina grinding balls deliver wear rates as low as <=0.01%.

-

This makes your alumina balls more durable than steel and lasts longer.

“Since switching to alumina balls 3 years ago in our grinding equipment, wear has significantly reduced, cutting our replacement costs by up to 45%.” —Jackt H., Procurement manager, CERM Mills.

3.2 High Strength

-

Your alumina balls offer flexural Strength of 386 ±12 MPa and high compressive strength.

-

With high mechanical strength, your alumina grinding balls withstand high impacts without deforming or fracturing.

3.3 Chemical Inertness

-

Steel introduces iron and metal debris into your milled products.

-

Your inert alumina ceramic ball doesn’t react with chemicals and offers 热导率 of around 30-35 W/(m·K). This ensures near-zero contamination in your industrial process.

3.4 Corrosion Resistance

-

Steel grinding balls contain iron, so they rusts when they come in contact with acids and alkalis.

-

Your alumina grinding balls do not react with chemicals and resists corrosion from solvents and salts environments.

“Shifting to alumina balls in our ore grinding helped us achieve pure and efficient grinding with no corrosion” —Abigail S., Process Engineer, Aether Grind

3.5 Electrical Insulation

-

Your alumina balls’ dielectric constant of 9.8 and resistivity of 1 x 10¹⁴ Ω·cm to 1 x 10¹⁶ Ω·cm ensure electrical insulation.

-

This makes your alumina ceramic ball ideal for your semiconductors.

3.6 High Temperature Resistance

-

Your ceramic ball withstands >1750°C without compromising structural integrity.

-

This temperature resistance improves performance and ensures reliability in your grinding processes.

3.7 Low Density

-

Your ceramic alumina ball provides a density of 3.99 g/cm³. While the higher density of steel sometimes offers better impact in coarse grinding, alumina is highly effective in fine grinding. Alumina’s low density reduces tool wear and consumption.

4. Alumina Ball Manufacturing Process

4.1 Preparing the Raw Material

-

>=99.99% purity alumina oxide powder is milled to achieve a uniform and fine particle size.

-

Binders are added to boost the formability of the powder.

4.3 Granulation and Spray Drying

-

Your milled powder is mixed to make a slurry, then sprayed into a dryer with hot air. This eliminates moisture and ensures particle uniformity.

4.4 Forming

-

Your alumina grinding balls are shaped through 等静压, extrusion and cutting, or dry pressing.

4.5 Drying

-

Your formed alumina balls are dried in ovens to remove moisture obtained from binders or processing.

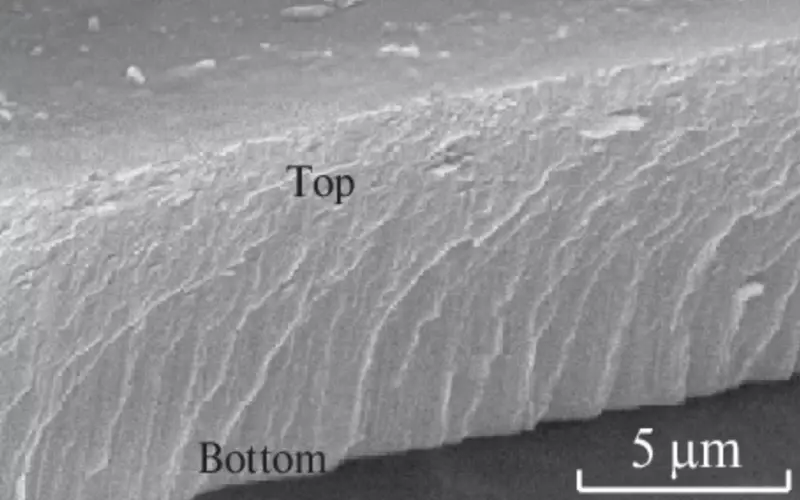

4.6 Sintering

-

Your dried green alumina balls are fired in kilns at temperatures >1600°C. This process ensures your alumina balls achieve a density (mass/ unit volume) of 3.99g/cm³, high hardness, and strength.

4.7 Finishing

-

Your alumina ball is ground and polished for precision in diameter tolerance.

-

The alumina grinding balls are then tested to ensure they meet ISO 9001 quality specifications.

5. Steel Grinding Balls Features

5.1 When Steel Grinding Balls Are Preferred

-

Steel possesses magnetic properties that are ideal for your automated assembly processors.

-

Steel exhibits higher toughness than alumina, making it more efficient in your high-impact coarse grinding & coal crushing.

5. Alumina Grinding Balls Vs Steel Grinding Balls Features

|

财产 |

ALUMINA BALLS |

STEEL GRINDING BALLS |

|

Hardness (Mohs hardness) |

9 |

7-8 |

|

抗弯强度(MPa) |

386 ±12 |

250-300 |

|

Temperature Resistance (°C) |

>1750 |

500-600 |

|

纯度 |

99.99% |

Metal & iron impurities |

|

介电常数 |

9.8 |

Infinite (conductor) |

|

重量 |

Lighter (ideal for fine grinding) |

Heavier (good for coarse grinding) |

|

密度(克/立方厘米) |

3.99 |

7.8 |

|

耐腐蚀 |

惰性 |

Corrodes (acids, salts) |

|

Wear rate |

≤0.01% |

Higher wear, frequent replacement |

Data source: Mater. Sci. Eng. 2025; 109(2): 021004; IEEE Trans. Compon. Packag. Manuf. Technol., vol. 12, no. 2, pp. 21004–21012, Feb. 2025

6. Alumina Balls Uses

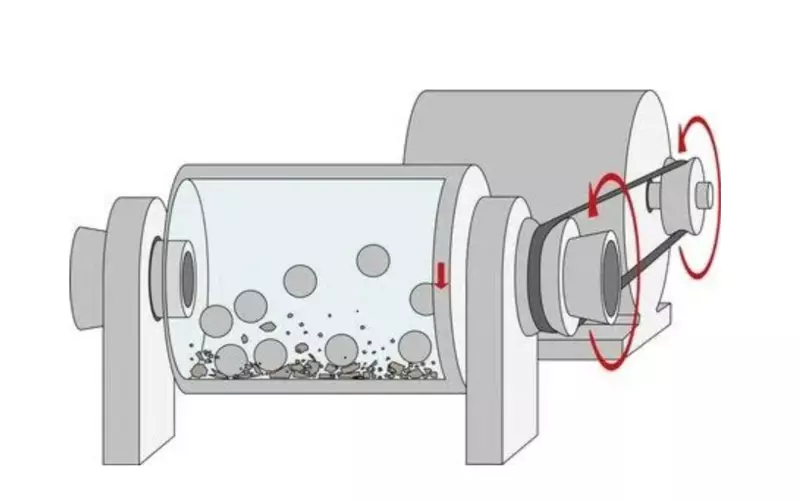

6.1 Grinding Media

-

Due to a hardness of 9 on Mohs scale and chemical stability, alumina grinding balls are used in your fine grinding of minerals and 陶瓷.

-

With superior wear resistance to steel, your alumina balls improves efficiency by >45% in your wet and dry grinding.

6.2 Milling Media

-

With purity >=99.99% and resistance to >1750°C, your alumina ceramic grinding balls provide stability and minimal contamination in your 球磨机.

6.3 Catalyst Support

-

Your alumina balls chemical inertness, ensure long-term stability when used as a catalyst bed support in your petrochemical processes.

6.4 Wear Parts

-

Your alumina balls are ideal for your valves, pumps, and seals. Their wear resistance ensures longer service life in abrasive conditions.

6.5 Adsorption and Purification

-

Your high purity alumina ceramic grinding ball porous structure makes it ideal for your water treatment and gas purification.

6.6 Electronics

-

Due to their insulation and thermal stability, your alumina balls enhance reliability of your 半导体 and microelectronics manufacturing.

6.7 Kilns and Furnaces

-

Your alumina grinding balls withstand >1750 furnace temperatures, enabling long-term stability in your kilns.

“Replacing steel with a high density alumina grinding ball stabilized our ceramic kiln operation. Downtime reduced by 30%.” —Wilsey R., Engineer, Kilnken Ltd

7. Alumina Balls Price

7.1 Initial Cost

-

High purity alumina ceramic grinding balls usually cost more than steel grinding balls.

-

This high alumina balls price reflects the high precision, high performance alumina ball manufacturing process.

7.2 Lifecycle cost

-

Your alumina ceramic grinding balls last significantly longer. Reduced wear, lower contamination, and fewer replacements lower total lifecycle cost.

-

Lifecycle analysis shows 40 to 50% savings across years. Select GGSCERAMIC® for ISO-certified lifecycle-tested solutions.

8. Selecting Your Ceramic Alumina Ball

8.1 How to Choose the Right Alumina Grinding Balls Type, Size, & Ratio

-

Your application determines the alumina balls size and ratio. Fine grinding benefits from smaller diameters, while coarse milling requires larger ceramic alumina balls. Inert ceramic grinding ball manufacturers provide solutions for chemical support.

8.2 Alumina Balls Manufacturers and Suppliers

-

Your inert ceramic grinding ball manufacturers should provide ISO-certified products and technical support.

-

Alumina ceramic grinding ball China suppliers deliver consistent quality at competitive prices.

8.3 Quality Considerations And Certification Checks

-

Ensure every batch meets ASTM and ISO standards.

-

Select suppliers that provide certification with tested purity, density, and wear rate specifications.

-

Select GGSCERAMIC® for ISO-certified solutions that guarantee consistency.

结论

Industries that prioritize efficiency, purity, and long-term cost effectiveness are shifting from steel to alumina balls. With high hardness, strength, temperature resistance, and inertness, your alumina balls are ideal for your grinding and chemical applications.

FAQs About Alumina Balls

Q: What are the advantages of alumina grinding balls?

A: Your alumina grinding balls offer hardness, chemical inertness, temperature resistance, and longer lifecycle than steel grinding balls.

Q: What are the alumina balls uses and applications?

A: Your alumina balls are used in grinding, milling, catalyst support, purification, electronics, and high-temperature kilns.

Q: Why are alumina grinding balls preferred over steel grinding balls?

A: Steel contaminates products and corrodes, while your ceramic alumina balls maintain purity, insulation, and stability.

Q: When may a steel ball have better impact than an alumina ceramic ball?

A: Steel grinding balls perform better in coarse, high-impact crushing, such as coal grinding.

Q: How does alumina balls price compare to other materials?

A: While initial alumina balls price is higher, lifecycle costs are lower due to wear resistance and durability.