Figure 1: Advanced ceramic manufacturing production in China

Finding a good advanced ceramic manufacturing supplier in China is harder than you think. China makes about 60% of the world’s 技术陶瓷, but there are large variations in quality. This guide covers 10 proven ceramic manufacturers in China, selection criteria including certifications and production capacity, and sourcing FAQs to help you choose the right supplier.

Why Source Advanced Ceramic Manufacturing from China?

China’s ceramic industry has invested more than $8 billion in research and development over five years. With this funding, world-class factories have been built to produce full-scale 技术陶瓷 for high-load applications such as silicon carbide, alumina and zirconia.

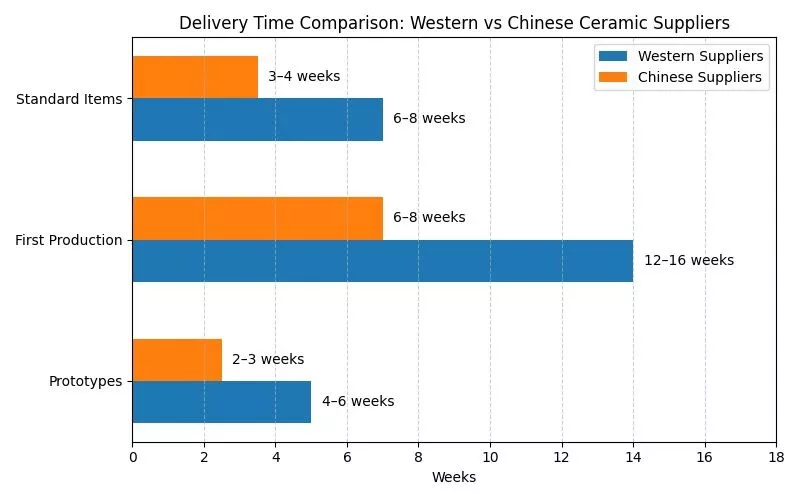

The difference in speed is overwhelming. Western suppliers take 12-16 weeks to deliver. Chinese ceramic manufacturing companies? It usually takes 6 to 8 weeks. If you choose the right supplier, the quality is comparable to international standards.

Figure 2: Chinese vs Western delivery

It also has a cost advantage. Chinese manufacturers present prices 30-50% cheaper than Western products. You can save 25-40% on the total cost even if you add the transport cost. This is a substantial benefit that is reliably returned to the budget.

What Makes a Top Advanced Ceramics Company?

Three things matter most.

-

Material specialization: Companies making everything usually do nothing great. You should choose a ceramic manufacturer specializing in specific materials. In the field of technical ceramics, experts surpass generalists. A silicon carbide expert knows the material - from 烧结 temperature to thermal properties.

Figure 3: Variety of technical ceramic products

-

Real Certifications: Ask for the actual certificate. ISO 9001 is the basic standard. Aerospace requires AS9100, and automotive requires IATF 16949. ISO 13485 is required for medical devices. Don’t take your claims on the web. Obtain the original certificate with the date of publication and expiration date.

-

Production: Top-class advanced ceramics companies produce more than 500 tons per year. Small businesses face issues with quality stability. We cannot afford to introduce spare equipment and a quality control system. Production is an indicator of stability.

Check the operating results. You should choose ceramic manufacturing companies that have more than 10 years of experience and have solved problems you have not yet encountered. Start-ups will learn at your expense.

Which Are the Top 10 Advanced Ceramic Manufacturing Companies in China?

1. GGS Ceramic (Gorgeous Ceramic)

Figure 4: GGS Ceramic manufacturing facility

Since 2006, GGS has produced industrial ceramics in three facilities (a total area of 30,000 square meters). We specialize in three major industrial ceramics: 碳化硅, 氧化铝 和 zirconia.

-

Product: 1600°C heating element, crucible, custom machining parts. Small lot production from a minimum of 50 pieces (most suppliers do not handle small orders). This flexibility supports prototype testing.

-

Capabilities: Sintering furnace is available up to 2200 °C. This is extremely important because the sintering temperature of the material must be higher than the working temperature. CNC加工 achieves tolerance of ± 0.01mm. Samples ready in 2-3 weeks versus industry norm of 4-6 weeks.

-

Certification: ISO 9001:2015, IATF 16949, AS9100D. All shipments are included in the test report. No extra charge for documentation.

Why Pick Them: Knowledge of common failure mode with 18 years of experience. Support is available within one day. Shipping to more than 40 countries, all export documents are on your behalf. No trouble at the time of customs clearance.

2. CeramTec (Suzhou Industrial Park)

A German company operating in China since 2001. Makes alumina and zirconia with European quality at Chinese costs. Integrate the rigor of German engineering into China’s manufacturing efficiency.

Obtained ISO 13485 certification for medical devices (rare among China suppliers). Medical certification requires strict quality control over industrial ceramics. Precision grinding to achieve a 0.1μm surface finish. Standard monthly production capacity: 1 million.

The parent company is supplied to a global medical device manufacturer. That reputation matters when your product goes into bodies.

Best for: Medical devices, automotive sensors, mass production.

3. Sinoma Advanced Materials

State-owned enterprises with facilities throughout China. Manufactures structural ceramics, bioceramics, and electronic ceramics. Basically all kinds of ceramics are published in the catalog.

-

Advantage: Raw material procurement by large-scale production. Alumina powder can be purchased in tons to reduce costs.

-

Disadvantage: Slow decision making. Government ownership means committee approvals. Supplies Chinese aerospace and defense programs.

Equipment is the highest level. The state-funded facilities are beyond the reach of private companies. However, the communication cycle should be prolonged.

Best for: Mass ordering, government procurement, domestic supplier priority.

4. Sanhuan Group Ceramic Technology

Founded in 1999, this publicly listed company makes electronic ceramics, not industrial. Mainly for smartphones, tablets, and consumer electronic devices.

Product: Ceramic materials for capacitors and substrates. Over 50,000 tons per year. Think smartphone parts, not furnace parts.

Capabilities: Supply to Samsung Apple series in automated volume production line. Obtained ISO 9001/14001 certification for quality and environmental management.

应用: Electronic components, consumer electronics, mass orders. It has strengths in the electronic field, but is not suitable for silicon carbide heating elements and industrial applications.

5. Suzhou Kema Technology

Established in 2009, Kematek specializes in ceramics for semiconductors and displays. Vertically integrated company that handles everything from powder to surface treatment in-house.

Products: Electrostatic chuck, heater, alumina, aluminum nitride, silicon carbide for chip manufacturing equipment. Supports large screen displays with maximum G 10.5 format.

Technical capabilities: In-house plasma spraying, anodizing and TWAS treatment. Recycling of old parts is also supported to reduce costs. Strict quality control is achieved through vertical integration.

Optimum field: semiconductor equipment, flat panel display, medical device, new energy field. Strength in high purity machining that emphasizes accuracy rather than mass production.

6. National Ceramic Materials China Industry

A major state-owned company operating since the 1980s. One of China’s largest ceramic manufacturers, owns a mine and manages it from raw materials to finished products.

Product: Alumina zirconia for heavy machinery, furnace interior material for steel mills, construction ceramic. Annual production is hundreds of thousands of tons.

Ability: Government-funded laboratories are responsible for aerospace and defense projects. Cost control and stable supply through mine ownership.

Application areas: mass ordering, government procurement, industrial equipment. With enormous production capacity but slow decision-making - full approval by the committee.

7. Shandong Sinocera Functional Materials

Sinocera, a publicly traded company founded in 2005, manufactures high-tech ceramic powders instead of finished products. It can be considered as a raw material supplier of electronic devices.

Product: MLCC powder for cell phone capacitors, PZT material to convert pressure to electrical signal (used for sensors and ultrasonic devices), zirconia for dental implants, honeycomb ceramics for automotive exhaust filters.

力量: China’s largest MLCC powder manufacturer. Strong patents and R&D capabilities. Advanced technical barriers eliminate competition.

主要应用: electronics manufacturers, automotive exhaust countermeasures, medical devices. Buy smart powders rather than custom ceramic parts.

8. China Electronics Technology Group Corporation

Established in 2002, CETC is a state-owned defense and technology complex and a core company in the field of electronics in China. It has more than 50 research institutes. We manufacture ceramics for high-tech systems developed in-house, and do not sell externally.

Product: 5G radar high frequency ceramic substrate, aerospace semiconductor package, military voltage sensor. Complete systems such as radar and satellite equipped with their own ceramic parts.

Capabilities: China’s largest electronic research network with unlimited government funds. Only in charge of national strategic projects.

Best for: Not available for general purchase. As a reference example of ceramic technology level in China.

9. Guangdong Province Sunlord Electronics

Sunlord, founded in 2000, is a publicly traded company leader in passive electronic components. They manufacture compact and high-performance components for circuit boards using advanced ceramic technology (LTCC).

Products: Chip inductors for power supplies and mobile phones, RF components for Wi-Fi and 5G, EMC filters to prevent signal interference, and LTCC multilayer modules for complex electronics.

Technical Power: The world’s leading inductor manufacturer holds thousands of patents. Supply Apple, Samsung, Huawei. Excellent in miniaturization technology, realizing astounding miniaturization of high-performance parts.

Application Areas: For electronics manufacturers seeking passive components that require mass production. They use ceramics as a manufacturing technology, and they do not sell ceramic parts themselves.

10. Fujian Torch Electronics

Established in 1989, Torch is a leading manufacturer of high reliability capacitors in China. As a listed company, they focus on the military, aerospace and industrial fields where breakdowns are not allowed.

Product: Military grade MLCC for withstanding extreme temperature and vibration, single layer ceramic capacitor for defense RF circuit, tantalum capacitor, energy storage supercapacitor, custom capacitor array module.

Technical Capabilities: China National Defense and Aerospace Program (Satellite, Fighter) Certified Supplier. More than 30 years in the field of electronics for harsh environments. Rigorous testing for mission critical applications.

主要应用: Defense-related companies, aerospace and industrial control equipment. Electronic components for high risk applications (not structural ceramic components).

How Do These Ceramic Companies Compare?

|

Company |

Main Focus |

尺寸 |

Best Feature |

|

GGS陶瓷 |

SiC, Alumina, Zirconia |

大的 |

Fast prototyping, low MOQ |

|

CeramTec |

Medical ceramics |

Very Large |

Medical certified |

|

Sinoma |

All types |

Massive |

Huge capacity |

|

Sanhuan Group |

Electronic ceramics |

大的 |

High-volume MLCC |

|

Suzhou Kematek |

Semiconductor ceramics |

中等的 |

Vertical integration |

|

National Ceramic Materials |

Industrial ceramics |

Massive |

State backing |

|

Shandong Sinocera |

Functional powders |

中等的 |

MLCC powder leader |

|

CETC |

Defense electronics |

Very Large |

Strategic projects |

|

Sunlord Electronics |

Passive components |

大的 |

Miniaturization |

|

Fujian Torch |

High-reliability capacitors |

大的 |

Military-grade |

What Should You Check When Picking a Supplier?

Check material capability: If you need 碳化硅 at 1600 °C, the furnace must reach a minimum of 2200 °C. High temperature is required for sintering.

Check capacity usage: Ceramic manufacturers with 95% operation cannot respond to emergency orders. Ensure a minimum of 20% margin. Direct inquiries about current orders.

Verify certifications: Verify the actual certificate with the issuance date and expiration date. Not enough to claim on the web. Call certification bodies if spending big money.

Test technical support: Send technical questions via email. Response speed and quality tell everything. Lack of communication before ordering leads to catastrophe during production.

How Do You Check Factory Capabilities?

Figure 5:Quality control inspection process

Ask about sintering methods—pressureless, hot pressing, or HIP. Different methods create different properties. Pressureless sintering is the cheapest. HIP creates the most dense parts but is expensive.

Get specific tolerance numbers. Do not accept vague claims such as “tight tolerance.” Can they hold ± 0.01mm? In which dimensions? Small parts are easier than large parts.

Check whether the composition inspection is performed in-house or outsourced. In-house inspection speeds up approval. An external inspection agency is a delay factor of about one week.

Verify R&D capabilities. Can they modify formulations or optimize your design for manufacturing? There are suppliers that only manufacture according to specifications, but excellent suppliers propose design improvements.

FAQ’s

What are the actual certifications that these ceramic companies require?

Everyone needs ISO 9001. Include AS9100 in aerospace, IATF 16949 in automotive, and ISO 13485 in medical. These are not optional, your quality team needs them.

What is the cost of Chinese ceramic production?

You will pay 30-50% lower than US or European suppliers. Upon shipping (incurs 5-8%), you are left with a savings of about 25-40 in total.

What are my expected minimum order quantities?

Prototypes: 50-100 units of good suppliers. Batches of production: 500 1000 common.

In case you require custom tools, purchase 2,000 -5,000 units to meet the cost of the mold.

Which region has the best ceramic manufacturers?

In Jiangsu province, particularly in Yixing city, there are more than 200 陶瓷制造 firms. The second is the Zibo region of Shandong.

How long do suppliers take for delivery?

-

陶瓷制造 prototypes: 2-3 weeks.

-

First production: 6-8 weeks.

-

Standard items: 3-4 weeks.

-

Rush at high-end prices.

Are Chinese companies able to do export documentation?

Best suppliers handle all this: invoices, packing lists, certificates, customs forms. Check this facility and then place an order.

What is the technical support of manufacturers?

The best ceramic manufacturing companies provide design consultation, material selection, prototyping and analysis of failures. Response times: Good (24 hours) to one week (slow).

Are small companies able to collaborate with large manufacturers?

Yes. Small orders are more expensive per piece and most factories accept them to establish relationships. A single test of $200 samples can save you 20 000 errors.

结论

Figure 6: Advanced ceramic honeycomb components

Your selection of the appropriate ceramic manufacturer will impact on quality, cost, and issues. Select suppliers that actually manufacture the ceramic and are certified. Test samples before big orders.

Have problems with 先进陶瓷? GGS Ceramic has been manufacturing technical parts since 2006. Our factory is ISO 9001, AS9100 and IATF 16949 certified. 联系我们 for samples.