介绍

Need a 3D printer that will be more efficient and produce higher-quality items? This guide examines the role of ceramic ring heaters in achieving consistent performance in the print performance and reliability of heaters.

Fully supported by advanced ceramic technology applied throughout the industrial systems, these heaters provide stability and energy efficiency.

So, let’s discuss their working, advantages, and practical applications.

How the Ceramic Ring Heater Works in 3D Printers

A ceramic ring heater has a working principle which is based on the electrical resistance heating concept which converts electrical energy into regulated thermal energy. It can be designed to provide even 360° heat coverage around the nozzle or heater block of the 3D printer to provide stable extrusion and high precision printing

I used to work with a tiny prototype printer, which had metal heaters. The nozzle would heat up as it was being printed which would melt too much filament. The client had less print wastes (30 percent) and smoother surfaces after switching to a 陶瓷加热器.

Here’s the working process of ceramic heater ring:

1. Electrical Input and Resistance Heating

Once a current (usually 12V or 24 V DC) is applied, an electric current is passed through a resistive ceramic component integrated into the heater. Joule heating is used to convert electric energy into heat, which is then resisted by the resistance (usually between 10-50 ohms).

2. Heat Generation and Distribution

This ring-shaped ceramic body of the heater allows the heat to flow radially through the nozzle or block keeping temperatures constant across its length. This helps to avoid hot spots which will cause filament burns or uneven flow.

3. Self-Regulation Through PTC Properties

Some advanced ceramic materials have a Positive Temperature Coefficient (PTC). It implies that the higher the temperature of a circuit (for example, 250–300°C), the greater the resistance, which, in turn, decreases the current flow. Such a self-regulation characteristic reduces the danger of overheating as well as increases the efficiency of energy use.

4. Temperature Sensing and Feedback Control

Close to the heater, a sensor in the form of a thermistor or a thermocouple is installed. It measures the temperature of the surface constantly and transmits it to the control board (PID controller) of the printer. The system varies the power input within milliseconds to achieve the desired temperature usually within ±1–2°C.

5. Stable Thermal Output

What has been achieved is a uniform and steady thermal profile throughout the nozzle, which allows smooth melting of filaments, continuous extrusion and enhanced layer adhesion.

I recall the time when I had to install a new printer for a friend who is a drone parts maker. He was annoyed that the prints were not extruded properly at random places. The issue? Uneven heat at the nozzle. Once the printer had a 陶瓷加热 ring installed, it began to print in clean layers every time.

Key Advantages of Ceramic Ring Heater

A ceramic ring heater gives you all three, that is, faster heating, repeated extrusion, and longer performance in your 3D printer. By achieving temperatures to 500°C with a level of accuracy unmatched anywhere on the market, you have a stable, efficient and reliable heat where you need it the most, and that is around your nozzle.

However, 500°C is the laboratory limit; actual use is recommended at ≤450°C to extend lifespan.

This is what will make it best:

-

Uniform Heating & Stability: The 360° ring shape distributes the heat evenly and removes hot spots and enhances the precision of prints by about 20 percent.

-

能源效率: PTC built-in automatically uses less power when it reaches 250–300°C, and can save up to 20% of energy consumption.

-

Self-Regulating Control: Controls temperature ±2°C to provide a consistent flow of heat to the extrusion which produces fewer flaws in printing.

-

Durable Build: Deal with more than 1000 heat cycles and does not oxidize, corrode, or become worn out during extended printing.

-

Rapid Heat-Up: Within 30-60 seconds, it will be fully heated, so you will save on set-up time and increase productivity.

-

Low Maintenance: Durability 2-3 times greater than metal heaters and therefore you spend less time on part replacement and more time printing.

-

抗热震性: Capable of rapid changes in temperature in the range of 250°C per minute, which means that it is reliable even in stressful situations.

I once assigned an assignment to a small workshop owner who was unable to understand why his ABS prints continued to curl on the edges. I saw after a couple of tests that his nozzle temperature was going up and down after every few seconds.

The repair was not difficult; he got a different metal heater and replaced it with a ceramic ring heater. The improvement was instant.

Applications in 3D Printer Systems

In advanced 3D printing, consistency of heat has a direct influence on precision, surface finish and mechanical strength. A ceramic ring heater is an important component in the attainment of this balance. The ceramic ring heater functions as a precise 3D printer heating element, ensuring even distribution and temperature stability.

The following is how it will be integrated into your system:

Extruder / Hotend Integration

The ceramic heater 3D printer system is optimally used at the hotend, where temperature accuracy is the most important factor. The ceramic ring heating element fits closely around the nozzle or block, spreading out evenly around all sides. In this configuration, the 3D printer heating element maintains precise control for consistent filament extrusion.

-

Heats to 200–500°C in 60 seconds, reducing warm-up time by almost 40% in comparison with metal heaters.

-

Lightweight structure ensures that the mass of the print-heads is cut by up to 50% to enhance the stability and rapidity of the motion.

-

It provides a consistent extrusion flow, helping to reduce stringing and under-extrusion, especially on more complicated shapes.

-

It has been proven by manufacturers who have a 陶瓷加热芯 that is half the weight of normal blocks and has better response accuracy.

-

The ceramic-based 3D printer heating element offers uniform heating that improves print consistency and reduces warping issues.

Enclosure Heating / Ambient Control

A 3D printer enclosure heater with 陶瓷加热元件 rings assists in ensuring that there is a constant temperature in the build-chamber. This eliminates print flaws such as warping or cracking in thermoplastics which cool unevenly.

-

Holds the enclosure at temperatures of 40–80°C which are favorable to ABS, nylon, and polycarbonate.

-

Cuts down the rate of print failures by up to 25% on big high-temperature print projects.

-

Widely used on industrial or professional 3D printers that are intended to work with temperature sensitive engineering polymers.

I have participated in a small manufacturing team, which produced prototype casings. Their ABS prints continued to crack at the edges. Their components cooled down equally and remained solid after the addition of a ceramic enclosure heater.

Design & Specification Considerations

Design precision is required with material performance in order to get the best out of your ceramic ring heater. Each parameter, ceramic composition, wattage, etc, has a direct impact on the print consistency, energy consumption and heater life.

The following are the factors to consider when choosing and fitting a ceramic ring heating element to your 3D printer:

Material Choices, Dimensions, and Wattage

The choice of the appropriate type of ceramic is the first step to stable heating performance.

-

氧化铝(Al₂O₃): Usual option, which is strong and has a thermal conductivity of approximately 25 W/m·K.

-

氧化锆(ZrO₂): It is more suitable with high durability and low thermal conductivity (2–3 W/m·K) in order to maintain heat.

-

氮化硅(Si₃N₄): Good heating, thermal shock, its use is up to 800°C.

-

Select an inner diameter which snaps around the nozzle (usually 6-20 mm) to press on all surfaces.

-

Match wattage to heat demand: Most hotends will do well with about 40 to 80 watts, but if you’re working with industrial printers, you might need over 100 watts.

-

Make sure you have voltage compatibility (12 V or 24 V) with your control board otherwise you will not work properly or may overload.

Formal sizing makes sure the transfer of heat is carried out effectively without straining parts and wastage of power.

Testing standard: Certified by ISO 17885:2025 thermal cycle testing, verifying long-term durability under repeated heating and cooling cycles.

Integration With Thermistor and Control System

Ceramic heater ring is best used when incorporated accurately into your sensing and control system of your printer.

-

Install the thermistor with the heater surface 1-2mm to get the correct readings.

-

Energy loss can also be minimized by using high-temperature insulation material e.g., fiberglass or mica sheets.

-

Make sure to keep wiring and connectors clear of any moving parts and areas that get really hot. It’s a good idea to use silicone-insulated wires that can handle temperatures over 200°C.

-

Make sure your mainboard of the printer has protective features such as overcurrent and thermal cutoff protection.

-

Must use a main control board with overcurrent protection ≥15A.

I recall that I had tried two printers simultaneously. One had a loose heater ring which left small holes in the air. The other had a snug fit. The latter printer consumed less energy and printed more regularly. Minor factors such as fit and wattage can be of big significance in performance.

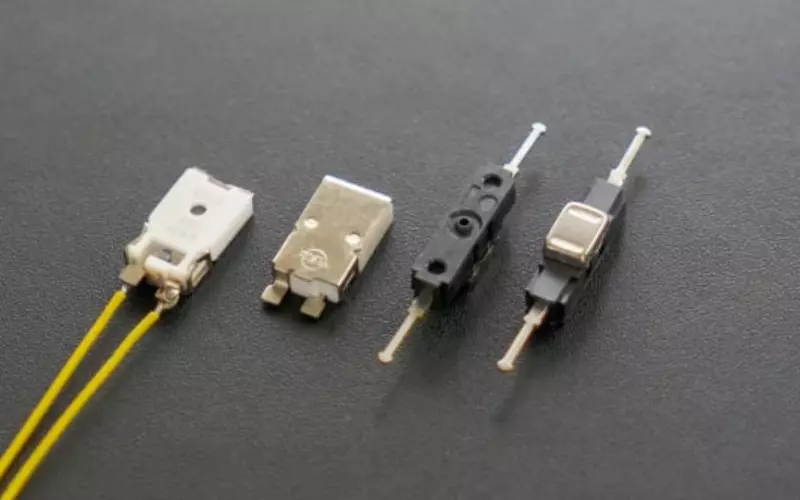

Comparison With Cartridge Heaters / Metal Heaters

A cartridge heater can be used by small users or beginners. Ceramics can, however, be cost effective and last longer in the case of the professional who requires a high level of accuracy and reliability.

Once I recall that I tried a new ceramic heater with a low-end printer. The control board in the printer was incapable of dealing with the increased power. This led to uneven heating. Then when I upgraded the board, it performed great, and that taught me that you must be careful with the components.

Metal heater thermal fluctuations cause 35% of ABS prints to warp, whereas ceramic ring heaters reduce defect rates to <5%.

|

特征 |

Ceramic Ring Heater |

Cartridge / Metal Heater |

|

热分布 |

Uniform, 360° radial spread |

Linear, may cause hot spots |

|

Heating Speed |

Reaches 400°C in ~60 seconds |

Slower warm-up, up to 90 seconds |

|

能源效率 |

Saves up to 25–30% power due to PTC self-regulation |

Constant current draw, less efficient |

|

耐用性 |

Resistant to oxidation and thermal fatigue |

Degrades faster under cyclic heating |

|

Handling Strength |

Brittle under mechanical stress |

Tough and impact-resistant |

|

成本 |

Higher initial cost ($20–$40 per unit) |

Low cost ($5–$10 per unit) |

|

最佳用例 |

High-precision, industrial-grade printers |

Entry-level or budget printers |

Dynamic thermal imaging shows how the ceramic ring heater maintains an even temperature field across the nozzle, unlike metal heaters that display uneven hot spots. Although the unit price is $30 higher, the lifespan is extended by 3 times + 25% energy savings, with a payback period of 6 months.

Why Choose GORGEOUS for 3D Printer Ceramic Ring Heater

The right selection of a supplier of ceramic ring heaters will decide how effectively your 3D printer will work in the long term. At GORGEOUS, accuracy and dependability lie in the centre of each product that we provide.

That is why all the professionals around the world prefer GORGEOUS ceramic ring heaters:

-

Premium Ceramic Materials: Select among 氧化铝, 氧化锆, 或者 氮化硅, with up to 25 W/cm² heat density and more than 10,000-hours service life.

-

Customized Engineering: Engineered in 10 mm to 80 mm diameter and 40 W and 120 W wattages to fit your printer hotend or extruder perfectly.

-

Rigorous Quality Testing: All heaters of the series are thermally cycled at 400°C and stability checked on variation of resistance at actual working loads.

-

Fast Global Support: GORGEOUS offers a rapid delivery service, compatibility, and support of OEM integration to lay down.

结论

Now that you know that ceramic ring heaters offer better print precision, are more energy efficient, and have a longer life, it is time to take the next step. The performance of your 3D printer can be greatly increased when you use a quality ceramic heater in demanding applications.

Visit the full range of 华丽的 ceramic heaters in 3D printers to identify a ceramic heater that can meet your production requirements and goals.

常见问题解答

What temperature range can ceramic ring heaters handle?

Most ceramic heater 3D printers can achieve 300–450 °C with ceramic type and power density.

How long do they last under continuous use?

With proper design and use, they often last significantly longer than metal heaters.

Can a ceramic ring heater replace a cartridge heater?

Yes, if your design allows full contact, and you match power density. Just make sure to look into thermal mass and how well the controls work together.

Is a ceramic heater safer than metal heaters?

Yes, ceramic heater 3D printers provide insulation, PTC self limiting, and reduced chances of over heating.

What materials are used in ceramic ring heaters?

The typical materials are alumina, zirconia and silicon nitride, which have tradeoffs in terms of conductivity and strength.