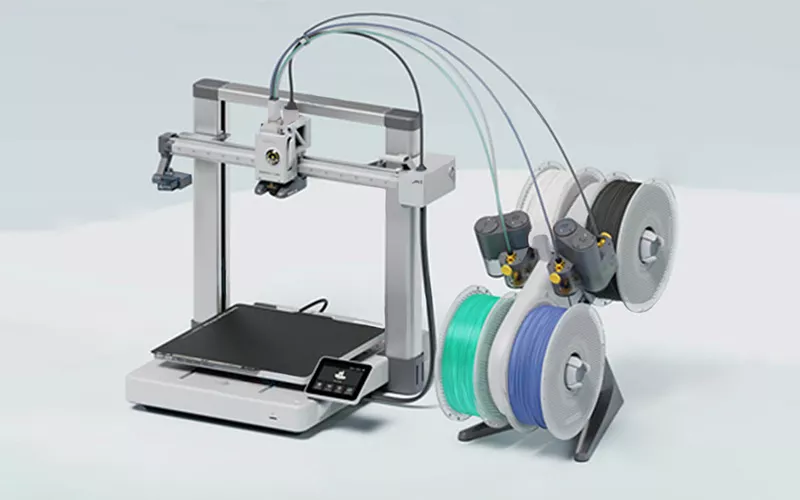

GORGEOUS ceramic heating elements, particularly MCH (Metallized Ceramic Heater), are widely used in 3D printers as a replacement for traditional heating elements due to their high efficiency, compact size, uniform heating, and precise temperature control. They are typically used in hot-ends to melt filaments and to heat the build platform to prevent warping and improve first-layer adhesion.

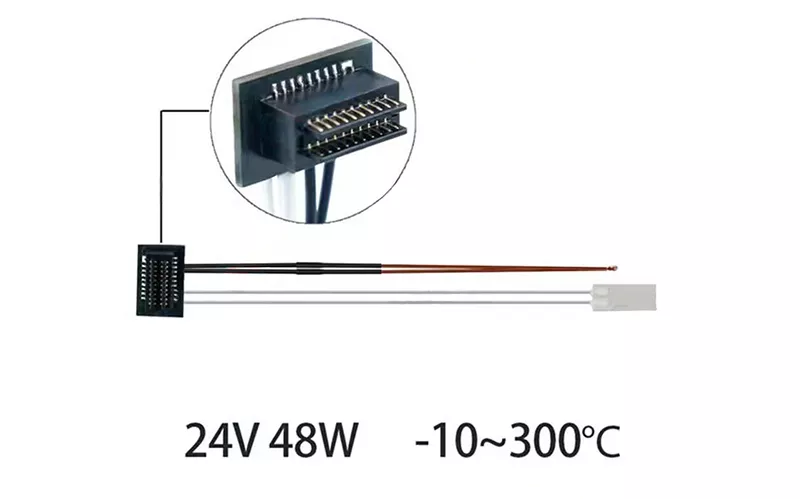

Basic Parameters of Ceramic Heating Elements for 3D Printers:

| 재료 | 알루미나 세라믹 |

| Operating voltage | 24V |

| Reference power | 48W |

| Size (length * width * thickness) mm | 15*7*0.23mm |

| Nickel wire length mm | 105 mm or customized |

| Terminal | Existing or customized |

| Casing | PTFE or as required300°C |

| Heating plate operating temperature | 300°C |

Advantages of Using Ceramic Heating Elements in GORGEOUS 3D Printers:

Fast and Uniform Heating: GORGEOUS ceramic heaters reach operating temperature significantly faster than metal-cased cartridge heaters.

Enhanced Safety: MCH alumina ceramic heating material automatically increases its resistance as it heats up, naturally limiting its maximum temperature and preventing thermal runaway.

Compact and Lightweight: Our ceramic heating cores are smaller and lighter than traditional heater tubes. This enables more compact and lightweight hot end designs, enabling faster and more precise printing, especially for input shaping and high-speed printing.

More Durable: GORGEOUS ceramic heating elements are resistant to thermal shock and high temperatures, making them rugged and reliable, capable of withstanding thousands of heating cycles.

Integrated Design: High-performance systems integrate the heater and thermistor directly into the nozzle block, creating a leak-proof, all-in-one unit.