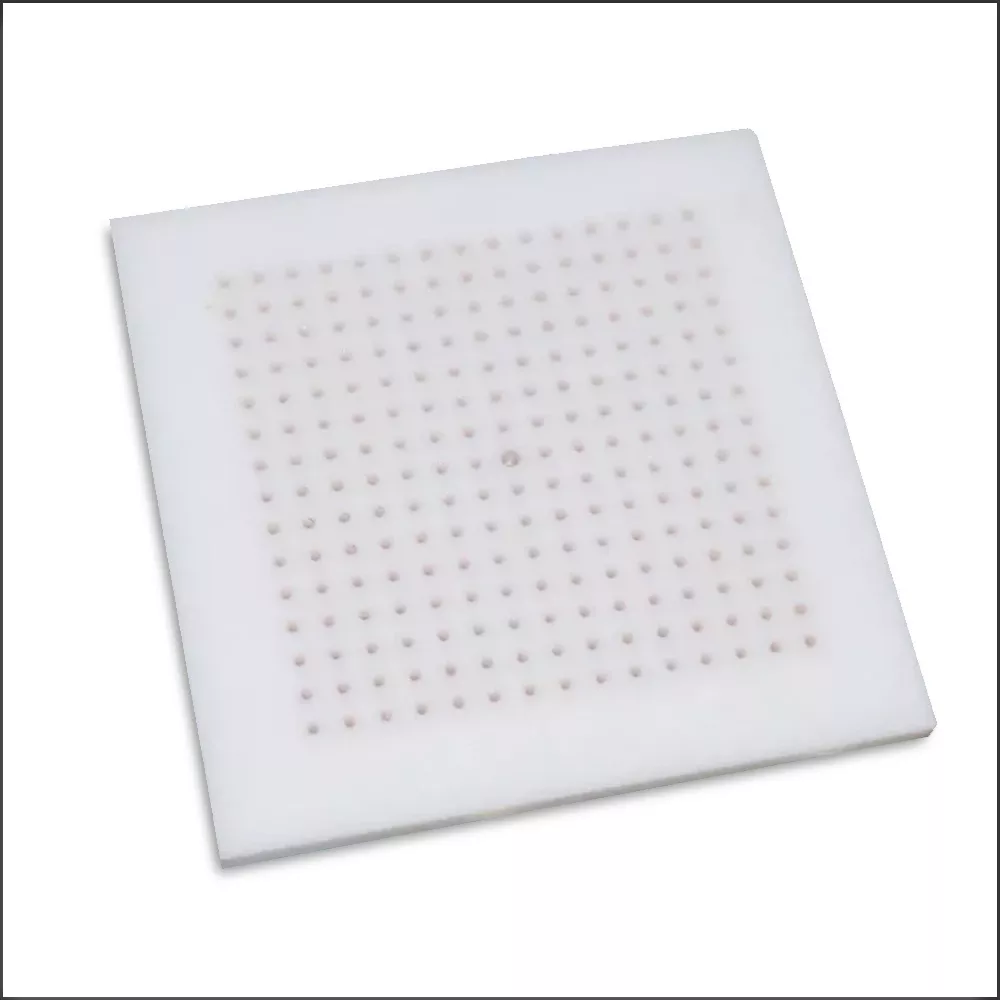

ركيزة الزركونيا

GORGEOUS is a leading international ceramic supplier, specializing in providing customers with zirconia substrate products used in the electronics and semiconductor manufacturing fields, and can customize the best solutions according to customer needs.

Zirconia Substrates

- Ultra-High Strength and Toughness: ZrO2 substrates offer significantly better hardness and fracture toughness than alumina and aluminum nitride, making them particularly suitable for applications requiring extremely high strength and impact resistance.

- Excellent High-Temperature Resistance: We offer yttrium-stabilized zirconia (YSZ) technology, enabling substrates to maintain dimensional and structural stability at temperatures up to 1500°C.

- Dense and Smooth Surface: After sintering, the substrates are dust-free, pore-free, smooth, and dense, ensuring airtightness and cleanliness, making them ideal for high-precision electronics and energy conversion applications.

- Laser Cutting and Custom Fabrication: We offer standard-sized substrates as well as custom-made complex shapes, including drilling, cutting, polishing, and metallization, meeting diverse customer needs from prototyping to mass production.

- Flexible surface treatment: supports polishing, coating and metallization layer deposition to improve the bonding reliability between substrate, chip and electrode.

Leading Global Manufacturer of Zirconia Substrate

GORGEOUS has over 15 years of expertise in high-performance ceramic substrate manufacturing, specializing in zirconia substrates, PCBs, and thin-film ceramic substrate processing services. Our products are exported worldwide, with long-standing partners in Europe, North America, Japan, and other regions.

Our advanced production lines and testing equipment ensure that every substrate produced meets the highest standards of precision, reliability, and thermal performance. From raw material processing to final inspection, every step is subject to rigorous quality control.

With GORGEOUS, you gain not only a supplier but also a trusted manufacturing partner capable of large-scale production and fast delivery.

Zirconia Substrate Product Gallery

Basic Parameters of Substrate

|

نقاء |

≥99% |

|

Appearance (Color) |

أبيض |

|

Chemical Formula |

أكسيد الزركونيوم |

|

Available Grades |

Ultra Tough Grade, Ultra Tough HIP Grade, 3YZ Ceramic Grade, Nano HIP Grade |

|

Maximum Working Temperature |

Up to 900 °C |

|

Standard Dimensions |

≤100 × 100 × 1.0 mm (custom sizes available) |

|

Material Composition |

ZrO₂: 94.8 ± 0.5%, Y₂O₃: 5.2 ± 0.5% (customizable on request) |

|

Dimensional Precision |

±0.001 mm |

|

تشطيب السطح |

Available with single-side or double-side polishing |

Substrate Standard Specifications

| مقاس | 100x100x1.0mm (Customizable sizes) |

| تلميع | SSP or DSP |

Zirconia Substrate Applications

Electronics and Semiconductor Fields

Electronic Circuit Substrates: Zirconia substrates can be used for packaging and supporting high-frequency circuits and power electronic devices, ensuring stable electrical performance.

Insulating Substrates: Zirconia substrates provide electrical insulation and mechanical strength for devices such as transistors, ICs, and LEDs.

Microelectronics Packaging: Zirconia metallized ceramic substrates can be used for electrode sintering and conductive layer deposition.

Optical and Optoelectronic Devices

Optical Support Substrates: Zirconia substrates can be used to mount and stabilize components such as lasers and infrared detectors.

Optical Communication Components: Zirconia substrates are widely used as substrates for optical fiber connectors and optical plugs due to their low loss and high mechanical strength.

Sensors and Medical Devices

Gas Sensor Substrates: Zirconium oxide itself can be used in oxygen sensors, and the resulting substrate serves as a support for the electrodes and sensitive layer.

Biomedical Devices: Used as substrates for dental restorations (crowns, bridge bases), and some implantable electronic devices.

High-Temperature and Harsh Environment Applications

High-Temperature Electronic Device Substrates: Zirconia is suitable for use in environments up to approximately 1000°C, offering stable performance.

Fuel Cell Substrates: In solid oxide fuel cells (SOFCs), zirconia substrates serve as the electrolyte or support matrix.

هل أنت قلق بشأن الحد الأدنى لكمية الطلب؟

Our zirconia substrates offer a minimum order quantity (MOQ) of one piece to meet the needs of diverse customers for small batch orders. Experience our service today.

لماذا تختار GORGEOUS؟

At GORGEOUS, you don’t have to worry about quality issues; product quality control is our top priority. Every zirconia substrate is manufactured to our customers’ exacting specifications and undergoes multiple inspections and tests, from raw materials to finished product, to ensure consistent performance and reliable quality.

Our factory is certified to IATF 16949:2016 for the automotive industry and ISO 9001:2015 for international quality management systems. This not only demonstrates our commitment to quality, but also ensures we can provide our customers with high-standard customized solutions.

نجاحاتنا في المرور شهادات العملاء

We have been looking for a reliable supplier of zirconia substrates. The products from GORGEOUS are not only dimensionally precise but also highly stable in performance. Their excellent insulation and high-temperature resistance perfectly meet our application needs. The whole ordering process was smooth and efficient—I would definitely recommend them to our partners.

مايكل أندرسون

We have very high requirements for the precision and stability of our zirconia substrates, and the products GORGEOUS provided fully met our standards. We are very satisfied with the dimensional tolerances, surface finish, and overall performance. The timely delivery and prompt after-sales response have made our production project progress more smoothly. We look forward to a long-term cooperation.

Li Wei

As a Technical Director, I set very high standards for material quality. The zirconia substrates from GORGEOUS showed outstanding precision and durability, and the delivery was perfectly on time. This is a trustworthy partnership, and we look forward to a long-term collaboration in the future.

Richard Collins

الأسئلة الشائعة

What are the differences between zirconia and alumina substrates?

Compared to alumina substrates, zirconia substrates offer higher toughness, better wear resistance, and lower thermal conductivity. However, alumina substrates offer a more competitive price.

Can the size, thickness, and surface treatment of zirconia substrates be customized?

Yes. GORGEOUS can customize the size, thickness, surface treatment (polished, porous, or metallized), and drilling of zirconia substrates to meet specific application requirements.

What are the main applications of zirconia substrates in the electronics and industrial sectors?

In the electronics and industrial sectors, zirconia substrates are primarily used in electronic circuits, sensor components, fuel cells, high-precision instruments, and medical devices.