On the coldest night in the winter, your furnace breaks down at 2 AM. You have a pellet grill igniter which breaks down right before your family barbecue. The ignition system fails and halts your production line of the factory. Ceramic igniters work even when metal alternatives fail and avoid such disasters. This complete buyer’s guide helps you to select a ceramic ignition system that will never let you down.

1. Why Ceramic Igniters Beat Metal Alternatives

1.1 The Science Behind Ceramic Ignition Reliability

I remember when I visited a warehouse of a heating equipment company. A failed metal ignition system was piled up there. Hundreds of bent, cracked, and corroded metal parts had a lifespan of just one to two years. On the other hand, the ceramic igniter systems use advanced materials such as أكسيد الألومنيوم and silicon carbide, and does not deteriorate even at extreme temperatures.

Hot surface ignitor technology works by heating ceramic materials to more than 2,500°F (about 1,370°C) within 15 seconds. The ceramic emits bright orange light and instantly ignites the gas. Metal cannot withstand this thermal stress and can deform or hot spot.

Specialized tests show that ceramic igniters equipment is 10 times longer than metal under the same conditions. The crystal structure maintains stability after more than 100,000 heat cycles

Fig 1: Ceramic vs metal igniter durability comparison

1.2 Hot Surface Ignitor Performance Advantages

The ceramic surface ignition system provides stable ignition performance under all weather conditions. Whether in Alaska’s -30°F (about -34°C) environment or in the Arizona Desert’s 120 ° F (about 49°C) environment, it works perfectly.

ceramic igniters resist corrosion caused by air and chemical vapors, including moisture and salt. According to one marina operator, the ceramic igniters system continued to operate even after being exposed to salt spray for five years. Metal failed in 6 months.

Electrical resistance is kept constant in ceramic materials. This means stable heating performance per ignition cycle.

2. What Makes High-Quality Ceramic Igniters Different

2.1 Precision Manufacturing Standards That Matter

Last year I visited a premium ceramic factory where ceramic igniters were being manufactured. Before packaging, workers tested each hot surface ignitor several times. This is the reason their products have long lives.

Leading manufacturers operate facilities with 56 CNC machine tools and 21 high-temperature furnaces. They produce ceramic igniters that are 0.001mm accurate. One heating distributor mentioned his warranty claims dropped by 70% after switching to premium-certified products.

2.2 Premium High-Temperature Igniter Options

Premium alumina ceramic igniters handle at 800-1000degC. The units are hot surface ignitors that warm up within 30 seconds providing immediate reliable ignition to furnaces and water heaters.

High-grade silicon nitride igniters work and can be used in automobile and industrial applications. They can take temperatures up to 1000degC and have good thermal shock resistance. Ideal in restaurant set-ups and industrial heaters that have to operate continuously.

Top manufacturers follow strict quality control standards to ensure every igniter works perfectly. Companies with nearly 20 years of experience use computerized testing systems that check each ceramic igniter before it leaves the factory.

3. Pellet Grill Igniter and Outdoor Cooking Applications

3.1 Why Pellet Grill Igniters Transform Outdoor Cooking

Last summer, a neighbor’s metal pellet grill igniter broke down during her daughter’s graduation party. As 50 guests waited, he tried manually igniting the newspaper. I lent a ceramic pellet grill ignition device as an alternative. It ignited instantly and operated perfectly throughout the day.

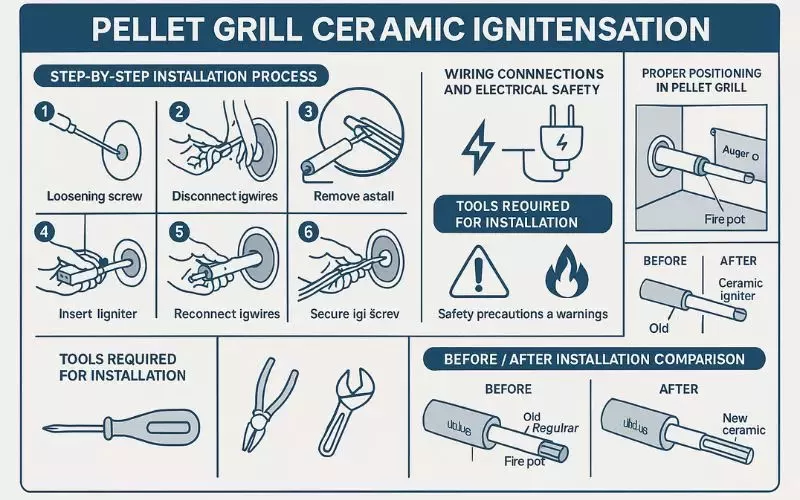

Pellet grill ignition system using ceramic technology eliminates the stress of ignition failure. Press the start button to ignite every time within 2-3 minutes.

Professional pit master adopts ceramic pellet ignition system for competition BBQ. Because stable ignition timing allows control of the amount of smoke generated and the temperature curve.

3.2 Pellet Smoker Igniter Selection for Different Applications

The amount of pellet smoker igniter depends on the usage pattern. The domestic consumers require medium-duty ceramic igniters which are dealing with 2-3 ignitions per week. Business processes require systems with high load capacities of 10+ daily cycles.

Pellet stove igniters made of ceramics have other difficulties than outdoor grills. Indoor units have to be certified to a higher safety standard and are required to deal with continuous operation.

Fig 2: Pellet grill ceramic igniter installation guide

Source: Professional outdoor cooking equipment standards

4. Industrial and Commercial Igniter Applications

4.1 Manufacturing Plant Ignition Requirements

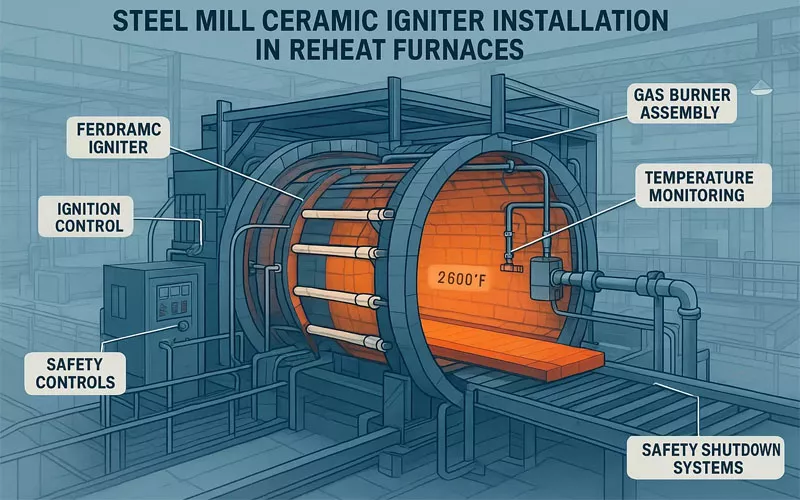

During the consulting project at the steel mill, we witnessed a loss of $10,000 per hour in production delays caused by the ignition failure. The factory manager showed an example of a ceramic ignition system reducing unexpected outages by 90% compared to conventional metal systems.

When operating an industrial igniter, it must withstand continuous operation cycles, harsh chemical environments and extreme heat. Ceramic ignition technology provides reliability to keep production lines running 24 hours a day.

Ceramic ignition equipment is used for safety-critical applications in chemical plants. Reliable ignition prevents dangerous gas accumulation and ensures proper combustion with waste gas flares.

Fig 3: Steel mill ceramic igniter installation in reheat furnaces

Source: Industrial steel processing equipment specifications

4.2 Restaurant and Food Service Applications

Kitchen equipment requires reliable ignition for stable cooking. One chef said the fryer igniter failed during the dinner rush and lost $5,000 worth of food stock. The ceramic ignition system prevents these expensive problems.

Commercial ovens, fryers and broilers use ceramic ignition devices for their ability to ignite instantaneously. Customers want hot food quickly. Equipment that takes 15 minutes to ignite will deprive customers of faster competitors.

Food safety regulations require a reliable ignition system that does not pollute food. Ceramic ignition systems meet NSF standards and FDA requirements for food contact surfaces.

5. Residential Heating System Igniter Solutions

5.1 Furnace Hot Surface Ignitor Selection Guide

A friend of my HVAC technician told me of the horror experience of a failed hot surface ignition system requesting emergency repair at 3 o’clock midnight. Ceramic units rarely fail unexpectedly. Before a complete failure, warning signs such as a decrease in ignition speed and a reduction in light emission are shown.

The electrical specifications must be precisely matched to replace the hot surface ignition system. Incorrect ampere rating causes early failure and fire danger. Please check the part number before installation.

Modern high-efficiency heating equipment uses a 2.5 ~ 4.5 amp low-current ceramic ignition system. Older systems may use 6-7 amperes. The composition of ceramic materials is different in these designs.

5.2 Water Heater and Appliance Igniter Applications

Ignition systems for water heaters face unique challenges such as humidity, temperature fluctuations and ventilation shortages. Ceramic ignition equipment is better in these conditions than metal substitutes.

The instantaneous water heater uses a ceramic ignition device for on-demand ignition. These systems require several thousand operating cycles per year. Only ceramic materials can provide the durability required for this harsh use condition.

In pool heater applications, ignition devices are exposed to chlorine-containing air and salt spray in coastal areas. Ceramic ignition devices are resistant to chemical corrosion that destroys metal parts in months.

Fig 4: Residential heating system igniter compatibility chart

6. Cost Analysis and Return on Investment

6.1 Total Cost of Ownership Calculations

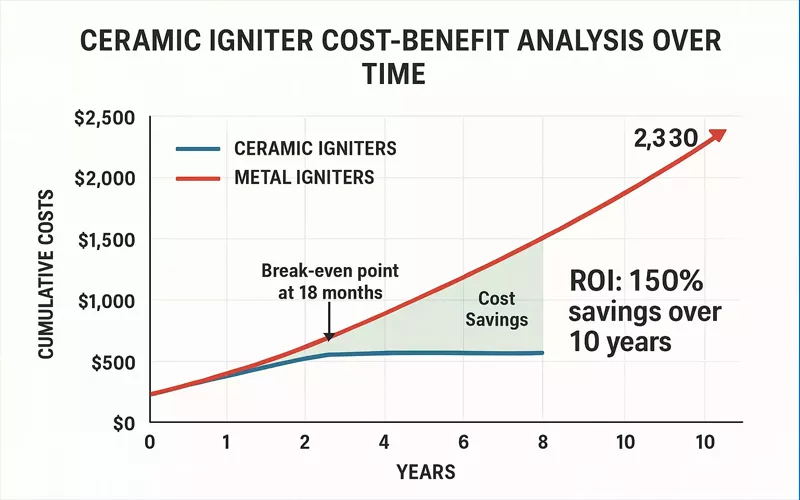

Ceramic ignition equipment has 2 to 4 times higher initial cost than metal. However, with a lifetime of 5-10 times, a positive return on investment (ROI) is realized within 18-24 months for most applications.

The labor cost of ignition equipment replacement often exceeds the material cost. Comparing ceramic ignition systems that require replacement every 8-10 years and metal units that require annual replacement, a significant reduction in service costs is possible.

6.2 Budgeting for Ceramic Igniter Upgrades

Plan to upgrade to ceramic during equipment overhaul and seasonal maintenance periods. A 15% to 25% discount is often applied for bulk purchases.

Consider upgrading the entire system rather than mixing ceramic and metal parts. Unified performance at all ignition points simplifies maintenance and troubleshooting.

Fig 5: Ceramic igniter cost-benefit analysis over time

Source: Professional maintenance cost studies

7. Installation and Maintenance Best Practices

7.1 Professional Installation Requirements

Installation of ceramic ignition equipment requires careful handling to prevent damage. I have witnessed the destruction of a $200 ignition device by a technician who grabbed it with pliers without the proper tool.

Clean and secure tightening of electrical connections. The loose connection causes voltage drop and reduces the performance and life of the ignition device.

7.2 Maintenance Schedules for Maximum Lifespan

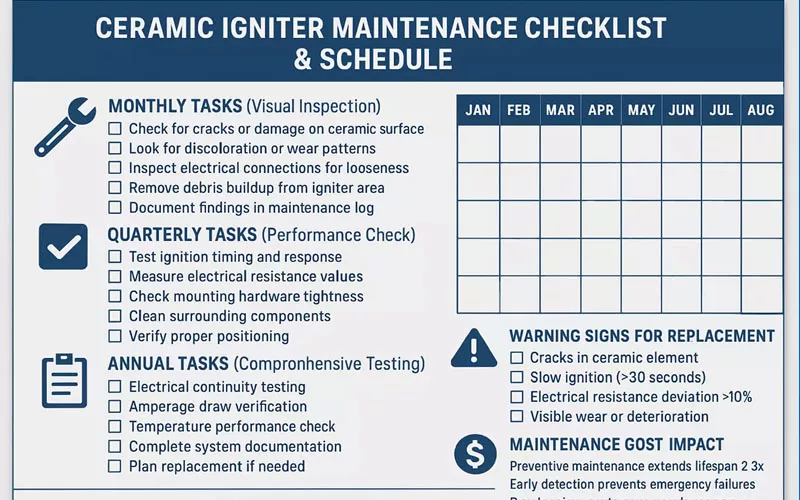

A monthly visual inspection will detect the problem before the failure occurs. Check the cracks, discoloration, and debris buildup on ceramic igniters.

The annual electric test verifies the appropriate current and resistance values. A ceramic ignition device with a deviation of 10% from the specification value must have a replacement plan.

Fig 6: Ceramic igniter maintenance checklist and schedule

Source: Professional maintenance standards

الأسئلة الشائعة

1. What is the average life of ceramic igniters?

Good ceramic igniters have a life of 8-12 years at home and 5-8 years in commercial applications. That is 3-5 times longer than metal ones. High-quality ceramic igniters made with strict quality control often last even longer than this because every part is tested before leaving the factory.

2. Is it possible to use a ceramic igniter instead of a metal one?

Yes, when the electrical specifications are the same. Majority of the hot surface ignitor units utilize standard voltage and amperage. Reputable manufacturers include detailed installation instructions with their products to make replacement easy. The upgrade is justified by the performance increase and increased lifespan.

3. Why do premium ceramic igniters cost more than regular brands?

Premium manufacturers use extremely pure ceramic materials (95-99.97% pure) and make each part with incredible precision. They follow strict quality testing at every step of production. Yes, they cost more upfront, but they last 10+ years instead of breaking every year or two. Many suppliers say they get 70-80% fewer complaints after switching to premium brands which means fewer headaches and service calls for you.

خاتمة

Ceramic ignition equipment delivers excellent reliability, long life and performance in all applications from residential heating to industrial processes. Although initial investment is high, it can be recovered in a short time by reducing maintenance costs and stable operation. From hot surface ignition systems to point fire parts for pellet grills, ceramic technology provides reliability. If you need professional advice, please contact GORGEOUS.