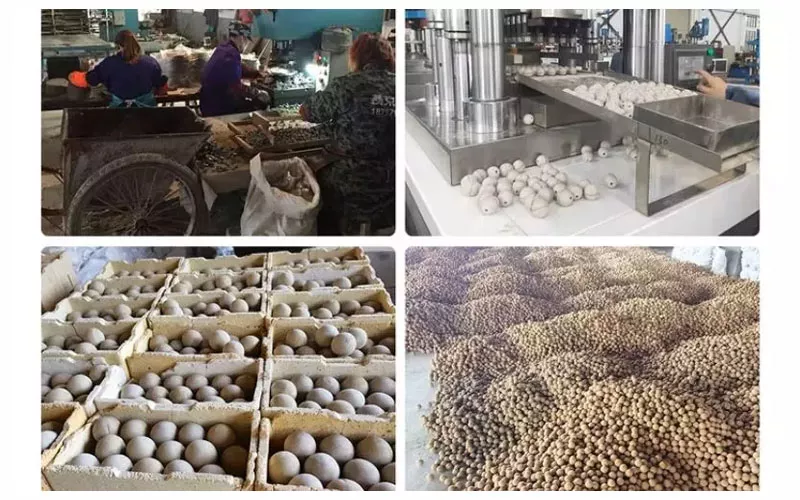

Fig 1: Alumina ceramic balls in advanced manufacturing facility

Source: Industrial manufacturing documentation ©CeramicsIndustry2025

You see white spherical media in chemical plants and manufacturing facilities. These are alumina ceramic balls that are well crafted and that contribute to significant industrial activities globally. This high-tech ceramic substance is far superior to the older ones. Once you know what your particular job requires, then you can choose the appropriate alumina ball solution to suit your own work.

1. What Are Alumina Ceramic Balls

Alumina ceramic balls are spherical materials that are produced using aluminum oxide (Al₂O₃). You achieve a high level of hardness, chemical resistance and thermal stability. These alumina balls outperform steel, plastic and conventional materials in rough conditions.

You take advantage of their distinct crystalline structure to resist wear and corrosion. The porosity and the surface property that is to be controlled in the manufacturing process is designed and predictive performance is achieved through a variety of operating conditions.

The current alumina ceramic balls are sintered using modern technology in order to produce high quality. You get uniform circularity, density and mechanical properties. Trusted manufacturers ensure specifications of performance based on your usage.

2. Types of Alumina Ceramic Balls

Fig 2: Types of advanced alumina ceramic balls

Source: Technical product catalog ©MaterialsGuide2025

2.1 Grinding Media Alumina Balls

You need grinding alumina ceramic balls as grinding media for size reduction and particle processing. This high density sphere provides efficient grinding without contamination. كرات الألومينا do not emit metal particles, thus maintaining the purity of the final product.

Ball mills rely on alumina ceramic balls for stable performance. You achieve precise particle size control with minimal media wear. Because pollution risk is eliminated, it is preferred in the pharmaceutical and electronic industries.

2.1.1 Grinding Media Performance Standards

Wear rate ≤0.1%/24h according to ISO 4700 standards. You achieve high standard grinding efficiency using low levels of media to operate at low costs.

2.2 Inert Alumina Ceramic Balls

Fig 3: Inert alumina ceramic balls for catalyst support

Source: Process engineering documentation ©IndustrialApplications

Inert alumina ceramic balls provide mechanical support in filling tower reactors. You use them to distribute gas and liquid flows uniformly. This maximizes the catalyst efficiency and extends the service life.

In petrochemical plants, inert alumina ceramic balls are essential for hydrogenation treatment equipment. Stable pressure loss and flow variance are obtained. Prevent channeling phenomena that reduce efficiency by spherical shape.

2.3 Packing Media Applications

You use alumina ceramic balls as packing media in distillation towers. These provide surface area for material transfer while maintaining low pressure loss. This improves separation efficiency and reduces energy consumption.

The water treatment facility uses كرات الألومينا for filtration applications. Mechanical filtration and adsorption properties can be combined. The spherical shape provides excellent backwash characteristics.

3. Industrial Applications

3.1 Chemical Processing

You find alumina ceramic balls essential in refineries and chemical plants. They support catalysts in hydrogenation treatment equipment and modification equipment. The catalyst life is greatly extended, reducing operating costs.

Inert alumina ceramic balls are used for gas distribution in sulfur recovery equipment. Maintain stable operation while reducing maintenance. The chemical inactivity prevents contamination of products.

3.2 Advanced Ceramics Manufacturing

Fig 4: Alumina ball production facility

Source: Manufacturing facility documentation ©ProductionTech2025

Technological ceramic manufacturers rely on alumina ceramic balls for powder processing. Precise particle diameter can be realized without metal contamination. Electronic ceramics require this purity level to obtain optimal properties.

For ball mill processing, alumina balls of diameter 5mm to 25mm are used. Select the size based on the hardness and target fineness of the material. The right choice reduces grinding time and energy consumption.

3.3 Mining Applications

For ore processing plants, alumina ceramic balls are used for grinding. Less consumption than steel media reduces operating costs. High hardness ensures efficient grinding while maintaining shape.

In precious metal treatment, grinding without contamination is an advantage. Prevents dilution of gold and platinum concentrates. As metal contamination is eliminated, the recovery rate is improved.

4. Technical Specifications

4.1 Physical Properties

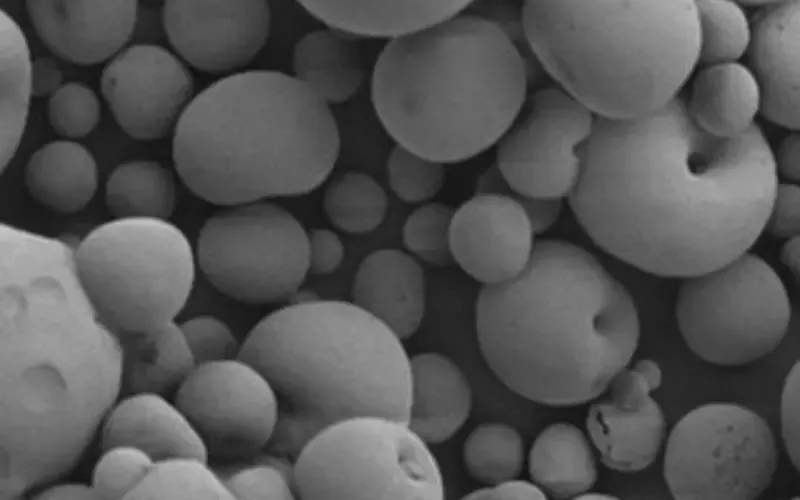

Fig 5: Alumina ceramic balls under microscopic view

Source: Materials science imaging ©TechnicalAnalysis2025

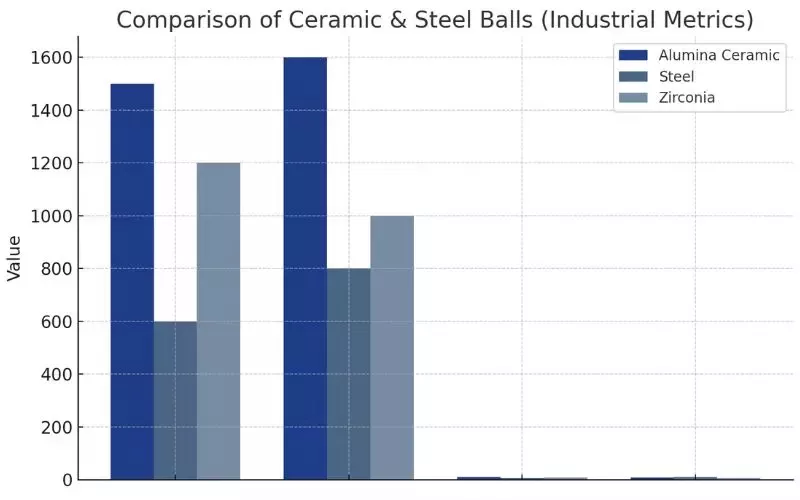

Alumina ceramic balls are hard materials and very strong. They can take up to 2500 Mpa of pressure without breaking and the HV of such is around 1500 HV. Depending on the type of ball, the weight of these balls ranges between 3.6 to 3.9 grams per cubic centimeter.

هؤلاء ceramic balls are resistant to heat. They are able to conduct heat at 20-30 W/mK and contract insignificantly when heated (8.0 x 10-6/degC). When engineers are designing equipment that will be hot or cold, they use these numbers.

4.2 Chemical Composition

طبيعي كرات الألومينا consist of 92-95% aluminum oxide (Al₂O₃). This suits them to most factory work. Very clean jobs require over 99.5% aluminum oxide in special high-quality balls. You should always review the certificates from your alumina ceramic balls supplier to ensure that the balls will fit your usage.

Small portions of other materials such as sand particles, iron and metal salts are also found in these balls. Certain special applications require balls that contain very little iron (less than 0.02%). Special uses of custom balls are available through different mixtures made by companies.

|

ملكية |

Standard Grade |

High-Purity Grade |

|

Al₂O₃ Content (%) |

92-95 |

99.5+ |

|

الكثافة (جم/سم³) |

3.6-3.7±0.05 |

3.8-3.9±0.05 |

|

الصلابة (HV) |

1,200-1,400 |

1,800-2,000 |

|

أقصى درجة حرارة (°م) |

1,600 |

1,700 |

Data source: ASTM C1327-2025 & ISO 14703:2025

Standards Testing standard: ASTM E1461-2025 laser flash method

Fig 6: Performance comparison

Source: Technical data visualization ©CeramicsData2025

4.3 Crystal Phase Structure Analysis

The special crystal structure of alumina ceramic balls renders them strong. The high temperature heating transforms the material into stable a-Al2O3 crystals.

الخصائص الرئيسية:

-

Crystal grain size:2-8 μm (standard), 1-3 μm (high-purity)

-

Very low porosity: <2%

-

Equal structure all over the ball.

This crystal structure renders the balls their high wear resistance and thermal stability. The industrial applications perform similarly and are of quality due to the controlled manufacturing process.

5. Manufacturing Process

5.1 Production Steps

Fig 7: Manufacturing process flowchart for alumina ceramic balls

Source: Process engineering diagram ©IndustrialFlow2025

The process of making the كرات الألومينا begins by selecting the very pure aluminum oxide powder. The companies select suppliers thoughtfully to ensure that the materials are of good quality. They do a test on the powder to determine what it is, and the size of the particles.

In modern-day factories, spray drying is employed to produce perfect round balls. This process causes the balls to become highly rounded and also evenly thickened. The workers categorize the balls according to their size to ensure that they fit perfectly to valuable tasks.

The balls become very strong as a result of heating them in ovens at temperatures of 1,550 to 1,750°C. This elevated heat causes them to be as tough as they can be and makes them resistant to chemicals. The balls are cooled gradually so that cracks do not form.

5.2 Quality Control

All of the كرات الألومينا are produced in accordance with the ceramic material rules by ASTM and ISO. With each order, customers receive test reports. These tests examine the material of the balls, their functionality, and whether they are the appropriate size.

Special computer systems are used in the factories to ensure that all batches of balls are of equal quality. This implies that the balls will do the same thing in critical jobs each time. The quality systems trace the origin of each ball and assist in improving the process even more over time.

6. Global Alumina Ceramic Balls Supplier Selection Guidelines

6.1 Manufacturer Evaluation

You must have suppliers with much experience in production of alumina ceramic balls. Ensure that they possess good quality control systems and ISO 9001 certificates. The factory needs to be large enough to produce all the balls you require.

Qualified alumina ceramic balls supplier helps you make good use of their balls in your business. They provide you with engineering assistance and correct issues when they arise. Special alumina balls can be made by the best suppliers, to suit your special needs.

6.2 Cost Analysis

سعر كرات الألومينا varies depending on the quality, size and the quantity you are purchasing. Large quantities allow you to receive lower prices. Long term contracts help stabilize prices and you will never run out of supply.

Consider all expenses, not buying price only. Take into account the transportation expenses of the balls and their efficiency. The quality balls are expensive initially but they save money as they last longer and perform better.

6.3 Global Sourcing

International alumina ceramic balls supplier companies offer competitive pricing and technical capabilities. Wherever you are in the world, you can shop around to get the best deals. Quality rules vary in different countries and therefore, you must ensure to look at them.

Consider shipping time, transportation expenses and the storage of the balls. You must strike a balance between money saved and supply issues. The proximity to suppliers implies that they deliver quickly and at a reduced cost.

7. Performance Optimization

7.1 System Design

Alumina ceramic balls do not work well without the proper system setup. You need to consider the speed at which liquids flow, the pressure decreases and the duration of the process. Work with your alumina ceramic balls supplier to select appropriate equipment that makes everything work more efficiently and less expensive to operate.

The employees should be aware of proper procedures involved in the start up and maintenance of the system. Operators must be taught how to deal with the ceramic balls. Frequent examinations will allow you to notice when balls are becoming old or become damaged.

7.2 Troubleshooting

Balls wearing out too soon are usually a sign that the wrong size was used or the conditions were too rough. You must find out what is causing the problem to prevent recurrence. Process settings and hardness of materials have to be adjusted.

Dirty balls occur when cleaning and storage is not done correctly. During handling, you should put in place rules that will ensure contamination is avoided. When dealing with sensitive processes it is very important to keep everything clean.

7.3 Dust Protection Requirements.

-

Workplace Safety Standards: When handling alumina ceramic balls, you should have proper dust control. Dust masks should be used by the operators and they should put on the EN 149:2025 FFP3-grade masks.

-

Occupational Exposure Limits: The concentration of alumina dust in the workplace should not exceed ≤1mg/m3 as OSHA 1910.1000 standards. You are advised to install proper ventilation systems and frequently check the quality of air.

-

Handling Precautions: Close-system material transfer should be used whenever possible. You reduce dust generation by designing equipment correctly and by regulated loading. All personnel must receive regular training on safe handling procedures.

FAQ’s

1. What factors determine the best alumina ball grade for your application?

Take into account the operating temperature, chemical environment and pollution requirements. High purity alumina ceramic balls are expensive but have excellent performance.

2. How do you calculate the required amount of alumina balls?

Measure the equipment volume and apply a filling density of 60% to 65%. Most alumina ceramic balls supplier offer free calculation assistance.

3. Is alumina ceramic ball reusable after use?

كرات الألومينا that are clean and wear less can be reused for less demanding applications. Compare economics and new material costs.

خاتمة

Alumina ceramic balls offer proven performance across industrial applications with excellent reliability. Optimal results can be obtained by selecting appropriate grades and working with certified suppliers. اتصال an experienced alumina ceramic balls supplier today for technical consultation and pricing information.